Products

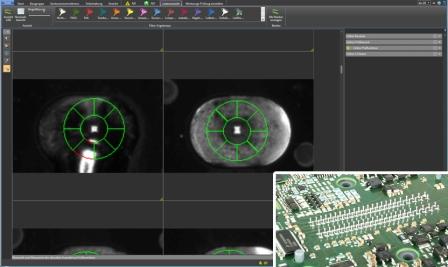

X Line 3D x-ray inspection system enables reliable inspection of THT and pin-in-paste solder joints in compliance with IPC quality standard through a combination of 3D AXI and 2D AOI. Max fault coverage at line cycle times reportedly can be achieved.  By scanning image acquisition, time-efficient quality control is possible. Hole fill levels, pin and pad wetting, bridging and solder balls can be detected with one system. Is for safe testing double-sided assembled PCBs. Covers top and bottom sides within a continuous process. Basis is real-time multi-angle image acquisition, allowing a complete 3D capture of the assembly. Integrated reconstruction methods based on planarGT provide detailed evaluation of the PCB under test layer by layer.

By scanning image acquisition, time-efficient quality control is possible. Hole fill levels, pin and pad wetting, bridging and solder balls can be detected with one system. Is for safe testing double-sided assembled PCBs. Covers top and bottom sides within a continuous process. Basis is real-time multi-angle image acquisition, allowing a complete 3D capture of the assembly. Integrated reconstruction methods based on planarGT provide detailed evaluation of the PCB under test layer by layer.

Goepel electronic, www.goepel.com

ECM-350 Table Coating Master works offline for small-quantity batch production. Features gantry robot (x axis) and table robot (y axis). Has ability to fix products using Multi Jig tool. Has an exhauster to inhale odor and an internal UV lamp.

Eunil, eunil-ha.com

JX-350 LED mounter supports a variety of LED nozzles and can place up to six diffusing lenses on top of the LED simultaneously for backlighting applications. Offers flexible placement system designed for LED lighting products and mid to large LCD display backlights.  Can support boards up to 1,500mm and laser centering for high-speed, high-accuracy placement.

Can support boards up to 1,500mm and laser centering for high-speed, high-accuracy placement.

Juki Automation Systems, www.jukiamericas.com

IM-4100 is designed to automate visual inspection processes for assembled components at facilities employing mixed production systems. Comes with a number of high-precision algorithms that use sensitive heuristic analysis to detect faulty or missing parts and determine whether factors such as positional alignment and installation angles are within acceptable limits.  Performs automatic pass or fail assessment of all necessary inspection points at approximately 0.5 sec. per inspection. Also utilizes QR and bar codes to acquire assembly data from the production control system in real time, allowing it to handle a wide array of items on mixed production systems.

Performs automatic pass or fail assessment of all necessary inspection points at approximately 0.5 sec. per inspection. Also utilizes QR and bar codes to acquire assembly data from the production control system in real time, allowing it to handle a wide array of items on mixed production systems.

Screen Holdings Co., screen.co.jp

Auto Slice & View 4.0 three-dimensional (3D) reconstruction software makes 3D imaging faster, easier, more accurate and cost-effective. Enables 3D structure and composition of samples at the nanometer scale. Works with all FEI DualBeam focused ion beam (FIB)/scanning electron microscope (SEM) platforms. Imaging can be combined with analytical capabilities, such as energy dispersive x-ray spectrometry (EDS) and electron backscatter diffraction (EBSD), to ensure no information is lost in sectioning of sample. Modifies automated procedures on-the-fly, with ability to add analytical signals if an unexpected feature is revealed. Imaging and analysis can be dynamically directed to selected areas of the section or applied only on certain slices to save time. Slice & View analyses can be performed at multiple sites to permit long, unattended runs over night or weekends. Advanced tiling and stitching capabilities maintain high spatial resolution over sections larger than a single field of view. New algorithms help to ensure uniform thickness of slices and precise and reproducible placement of each cut, for higher accuracy. Redesigned interface optimizes user guidance and ensures critical information is presented, if needed. Prompted workflow approach streamlines setup of automated procedures, and any procedure can be tagged as a template to serve as the basis for future analyses.

FEI, fei.com/software/auto-slice-and-view

JT 2127-Flex hardware adapters are for testing of a variety of DIMM and SODIMM sockets (sizes and styles) using a JTAG/boundary-scan controller and supporting software. Are said to provide pin-point diagnostics from a known-good test interface to assess whether the socket is soldered correctly. Modular system comprises two basic elements: 1) a high-speed multi-channel IO module – JT 2127/DMU, and 2) a personality adapter for the chosen DIMM type – JT 2127-Flex xxx.  The combination permits test signals to be sent to and from the boundary-scan source device on the UUT performing a thorough check for open pins and short circuits. In addition the voltages on the power pins of the DIMM socket are also measured. Currently supported DIMM types are xxx = 204-3, 244-mi3, 260-4 & 288-4. Other DIMM formats can be supported upon request.

The combination permits test signals to be sent to and from the boundary-scan source device on the UUT performing a thorough check for open pins and short circuits. In addition the voltages on the power pins of the DIMM socket are also measured. Currently supported DIMM types are xxx = 204-3, 244-mi3, 260-4 & 288-4. Other DIMM formats can be supported upon request.

JTAG Technologies, jtag.com

Press Releases

- Indium Corporation Introduces New Flip-Chip Flux for Semiconductor Devices

- KOKI to Showcase Analytical Services and New HF1200 Solder Paste at SMTA Guadalajara 2025

- ROCKA Solutions to Exhibit at SMTA Guadalajara Expo & Tech Forum 2025

- Libra Industries Expands Precision Fabrication Capabilities in Guaymas with Advanced Amada Laser System