Coating Capillary: Now You See It?

Solve capillary issues by increasing solids content.

Solve capillary issues by increasing solids content.

It is very important to control conformal coating thickness on a printed board assembly. Problems with coating over different surfaces, particularly sharp corners that can lead to shorts from tin whiskers, have been demonstrated many times.

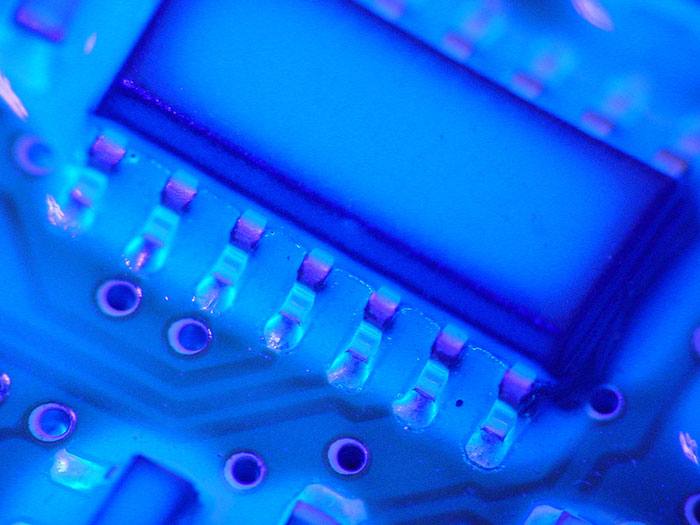

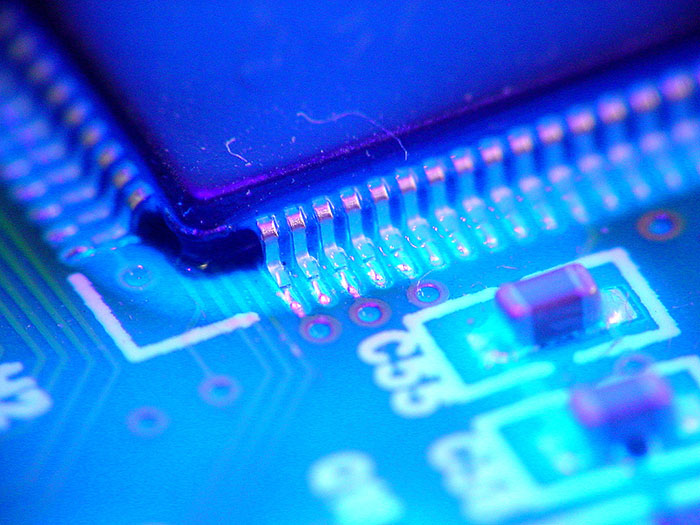

FIGURES 1 and 2 show capillary action on an SOIC and QFP, respectively, where the thickness of the coating is much higher around the leads and the body of the devices. With very high fluidity and spray coating, liquid capillaries under the package are starving the area of the board close to the edge of the pads.

Figure 1. Capillary action on an SOIC …

Figure 2. … And QFP.

The solution to this is to increase the solids content in the coating material. Also, if the board fabricator is new, check the solder mask. (And never change something that is working unless the consequences have been properly considered.) Just because the spec looks the same, it may not be.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging