Dross or Oxide Short Defects

Poorly maintained baths or improper wave settings can lead to whiskers.

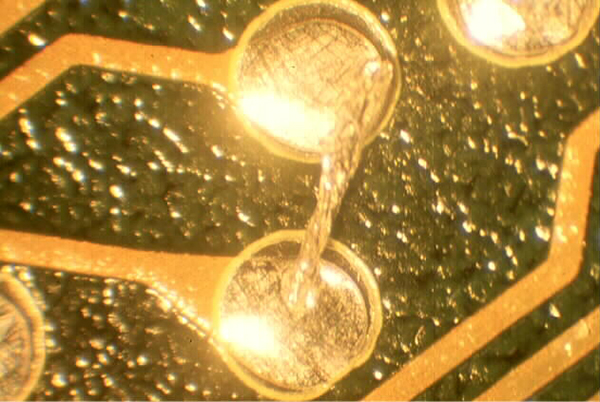

A solder whisker or a dross short is surface contamination found after soldering due either to a poorly maintained solder bath or incorrect setting of a wave. If a solder bath is poorly maintained, dross can be present in the ducting below the solder surface. When the wave operates, any dross can emerge randomly in the wave and contact the board and form micro shorts.

In the case of the back flow on a lambda style wave, the solder should flow at the same speed as the board or slightly faster. The board displaces any surface oxides on the surface of the wave before it can contact the base of the board. If the wave stops flowing before the board exits the wave, the board will contact the surface oxide, leading to what is sometimes referred to as “snail trails.” This can also be seen on waves running nitrogen where only the surrounding areas of the wave are inserted.

Similar micro shorts have been seen during wave soldering in a Pb-free process where the copper level is excessive and the temperature has permitted SnCu needles to form and flow in the wave. The same is true if the surface of the tank becomes eroded, permitting SnCuFe needles in the bath. Both these contamination issues can lead to very fine needle-like solder shorts. The excess copper can be overcome by balancing the copper levels with tin. SnCuFe is a real problem not only to the system but also the extremely expensive alloy, which will need to be changed.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the “Defect Video of the Month,” presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

Figure 1. Solder whisker bridging two conductors.

Chris Hunt is with the National Physical Laboratory Industry and Innovation division (npl.co.uk); chris.hunt@npl.co.uk. His column appears monthly.