Automated Dispensing for Electronics Manufacturing

An overview of today’s adhesive application technologies.

Automated dispensing of electronic materials in fluidic form is employed across the full range of electronics manufacturing, from board-level assembly to semiconductor applications. Materials dispensed can range from very low (water-like) to very high (toothpaste-like) viscosity and encompass many different functions. These include solder paste to electrically connect components, encapsulants to protect devices from atmospheric conditions, thermal interface materials (TIM) to help dissipate heat from parts, adhesives to attach parts to a substrate or assembly, and others.

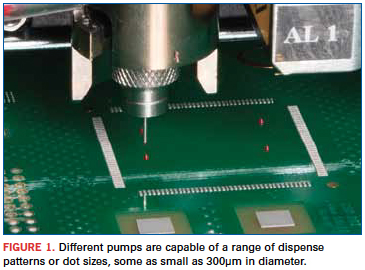

Each material may be dispensed in a range of dot sizes or complex lines and patterns, depending on application requirements (Figure 1). Common applications include underfill, selective coating, fastening, dam and fill, potting and dielectric dispense. Shape and function are determined by the type of pump mounted in the dispenser. A dispenser may be fitted with more than one pump head type so that it can perform multiple dispense operations on a single substrate. For example, for an individual PCB or workpiece being processed, one pump head might be dispensing tiny adhesive dots 300µm in diameter to hold very small passive or chip components onto the assembly, while the other head is performing an encapsulation operation on a wire-bonded chip, or applying a selective coating.

Dispensing is a complex process with many different controllable variables. But essentially all dispensing is divided into two main sets of parameters: material and machine. Material parameters include such variables as viscosity, temperature stability, flow behavior, absence of air, wetting behavior and homogeneity. Machine parameters are all those software parameters a given system uses to be able to execute the process of dispensing the material.

With automated dispensing, there are different types of pump technologies used to precisely meter the deposition of materials, ranging from traditional auger-screw constructs to piston and streaming designs, and even cutting-edge technologies that involve noncontact and radical new fluid management technologies. Each type has its pluses, from reliability to speed to precision, whether the application is dot dispensing or streaming lines of material. Pump designs incorporate special materials or features to accommodate the types of material that they are dispensing; for example, some types of adhesives are filled with highly abrasive material that can quickly wear out pumps that aren’t built with carbide and sapphire components.

As requirements for smaller dot sizes and higher throughputs increase, OEMs must work even harder to offer dispense systems with higher accuracy and higher speeds. We see this in the new pump technologies offering faster cycle times and higher degrees of process control through more sophisticated software and more robust X, Y gantries for stability. To obtain higher accuracy and speed, DC linear motors and linear encoders are used to move the dispense heads around quickly and with precision. Proper gantry design enables higher speeds and accelerations up to 3g without sacrificing accuracy. With today’s automated dispense systems, speed, accuracy, and dispense control are paramount. Machine vision systems ensure accuracy, and more user-friendly GUI and software tools speed teaching and setup.

In terms of pump technologies, in addition to greater dispense control and smaller dot sizes, ease of setup and simple maintenance without overly involved cleaning procedures are goals, driven by the growing number of high-mix product environments where downtime between different product runs is money out of pocket.

Dispense equipment is trending toward smaller, more compact footprints to maximize limited factory floor space without compromising throughput. This often means dual-lane processing capability. Dual-lane processing permits parallel loading of production parts onto two lanes for continuous dispensing, eliminating lost time in non-dispensing activities such as material flow-out and substrate loading/unloading.

Michael Martel is product marketing engineer at Speedline Technologies; mmartel@speedlinetech.com.

Press Releases

- PulseForge Makes Major Breakthrough Which Allows Flux-less Soldering in an Ambient Environment

- Panasonic Connect publishes case study on delivery of its surface mount technology (SMT) equipment to Dixon Technologies, one of India’s largest EMS companies

- CE3S and Desco Industries Announce May 2026 ANSI/ESD S20.20-2021 Certification Webinar Series

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging