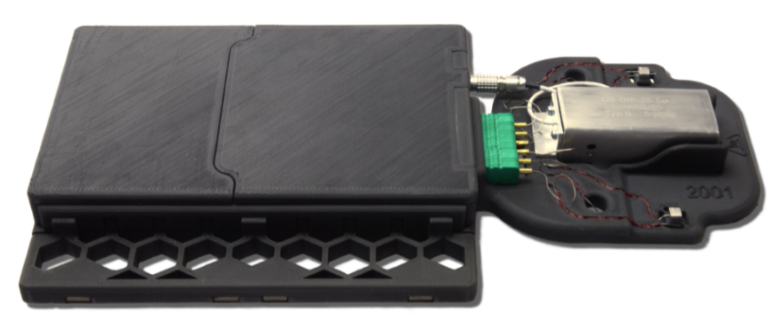

AHMT Releases Omnibus Soldering Oven Data Logger

Omnibus data logger wirelessly analyzes the settings of soldering ovens as well as conveyor belts in SMT production lines and returns the measured values live.

Helps detect faulty settings, necessary maintenance work and possible production errors at an early stage. Modular system can be tailored to customer requirements. Measures track widths and conveyor belt transitions for fully automated systems, track widths in continuous ovens, residual oxygen content in plants of any kind, mechanical shock and tilting inside and outside the furnaces, and temperature profiling In addition to the measured variables, the geometry of the data logger can also be completely customized. Handles operating temperatures up to 300°C. For reflow, vacuum, conduction soldering (hot plate), selective and wave soldering, plus coating, curing and drying.

AHMT

Press Releases

- SMarTsol America Expands Partnership with ASMPT and Strengthens Regional Coverage in the United States

- Absolute EMS Appoints Mark Sika as President to Lead Next Phase of Growth

- Beyond Torque: New Seika Machinery Webinar Reveals How Strain Gage Technology Exposes Hidden Bolt Axial Force Risks in Battery and PCB Assemblies

- New SASinno Ultra-i1 Gives K&F Electronics Added Flexibility in Selective Soldering