The Heat is Off: Could a New Platform Revolutionize Soldering?

New technology from Safi-Tech means cold solder joints might no longer mean defects.

I’ve been covering the soldering industry for more than 30 years. During that time, I’ve seen lots of innovations come and go. I remember when an engineer from Hughes was using citric acid from oranges as a flux. And when Bell Labs introduced its first water-soluble flux. I recall when nitrogen was first used in convection reflow environments and when no-clean pastes were rolled out and dismissed as lab curiosities.

Last July, Indium Corporation announced a partnership with Safi-Tech, Iowa-based startup that is creating no-heat and low-heat soldering and metallic joining products.

They call these supercooled molten metal products, and they have direct application to electronic soldering.

Dr. Ian Tevis, president and cofounder of Safi-Tech (safi-tech.com), and Dr. Andy Mackie of Indium Corp. (indium.com) discussed this supercooling platform with PCD&F/CIRCUITS ASSEMBLY in September.

Mike Buetow: The electronics industry has been chasing lower-temperature solders for decades. That effort really sped up as SAC solders took hold in the wake of the European mandates to eliminate lead But tin-lead has a higher melting point than lead, so the transition away from tin-lead eutectic or 60/40 meant higher reflow temperatures, which in turn means more stress on the bare board laminate, the typically plastic component packages and so on, not to mention the higher processing costs due to the increase in energy consumption.

Naturally, then, it would be a big deal if we could process solder with SAC 305 characteristics at a much lower temperature. Ian, what exactly is this new platform you’ve created?

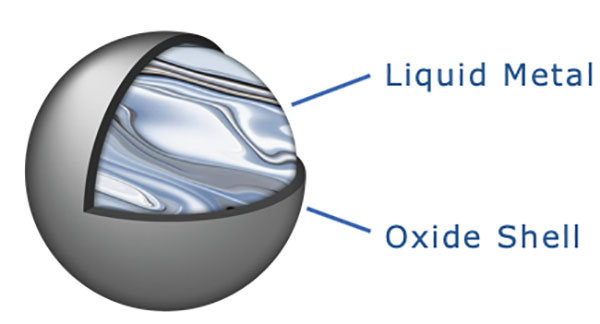

Ian Tevis: This supercooled liquid metal product is a new form factor for soldered metal alloys. It’s a core shell microcapsule. We call it a microcapsule; others might call it a particle or a solder ball. It looks just like a regular solder ball, just a little bit smaller with a little bit extra on the shell.

It’s a core shell structure, meaning the solder on the inside is the metal alloys that you know and maybe love – SAC 305 and other metal alloys – and we put a proprietary shell on that. That gives users of the solder material access to the supercooled liquid state that, instead of being a liquid above the melting point, is a liquid below the melting point. That’s what’s being called a “supercooled liquid state.”

We stabilize that so users can access it and use a liquid version of SAC, bismuth-tin or other different alloys at much lower temperatures than normal.

MB: So the IP is in the shell?

IT: The IP goes toward the shell, which is like the magic that makes the technology happen, but there’s also some unique application-specific IP. There’s new ways of using it. We have a chemical-based process like a solder paste would have: a chemical-based flux to remove our oxide organic shell.

Also, there’s IP on what we call mechanical activation, or compression-based techniques, where we take a little squishy microcapsule and squeeze out all the liquid metal, and it can flow out and form the solder joint that way. (Ed.: A video of showing a supercooled metal ink particle poked with a sharp metal probe that triggers the ink particle to turn solid can be seen here: https://www.youtube.com/watch?v=XYXEihvD78o.)

MB: You’ve started with SAC 305. Are you working on any other solder types?

IT: The technology is really a platform, and SAC 305 is the biggest target, but we’ve applied it to successfully to other platforms, bismuth-tin being one. There’s growing early interest in lower-temperature solders, and bismuth-based solders are easily accessible because of their lower melting point.

We’ve also looked at some lead-based solders because there’s still a need. If you could process a tin-lead solder joint at lower temperatures there’s a benefit. But, it’s primarily been SAC 305 and tin-bismuth.

Figure 1. The oxide shell applied to molten alloy prevents nucleation and permits the metal particles to remain liquid at temperatures significantly below the freezing point.

MB: What solder powder sizes have been tested to date?

IT: The key to the way the technology works is the solder spheres have to be small. We’re talking one to 10 micrometers in diameter. We can go a little bit bigger. We don’t really go smaller than that. And I’m not even sure if there are specifications about what sizes those are yet, but that’s about the size we work on. Maybe Andy can speak more toward if type 9 and type 10 powder sizes have been truly defined.

MB: Type 9 or type 10?

AM: I’ve seen it. It’s been talked about in song and legend. One of our competitors was talking about this about 15 years ago when I first started at Indium, and we’re still sort of not seeing that powder size out in the market for standard system-in-package and those kinds of applications. Having said that, the technology itself is something that we’ve been working on with Safi-Tech for about six years.

We’ve been working together quietly in the background of finding applications for this. We really got excited about six months ago when we realized that this was going to be potentially usable in some real-life situations. It was no longer a laboratory curiosity. It was going into the real world, and it’s at this point that I made the decision to jump in and work together to actively promote this to the electronics assembly industry.

MB: Where do you stand in the testing, and what types of machines have you used this on so far?

IT: We’re early in the testing. We have done some basic-level die shear-type tests and thermal shock for our SAC 305 prototype. We’ve sent them out for external testing for thermal shock at-40° to 110°C, 30 minutes each for thermal shock at 1000 cycles. This is a BGA attached on immersion silver FR-4, so it’s kind of our test vehicle.

The BGA works well with our system. Immersion silver gives a nice surface finish for us to do our attach, so they’re surviving the 1000 cycles. There’s a little bit of voiding that’s occurring, but no full cracks. That early-level testing is promising for that, and we’re working on the flux. The flux being used on a SAC 305 microcapsule now at 180°C, versus 240°C; that flux will look different and similar in some ways, but it has to be designed to work on our shell and at a lower temperature. Some development needs to go on there, as well as print development. We’re experts at making microcapsules, but supercooling flux development is its own separate beast to tame.

MB: What soldering temperature are we talking about?

IT: For SAC 305, we’re doing some processing at 180°C, and as low as 165°C. It’s still in prototype. For some select customers, we are doing trials and demos, but for bismuth-tin, which is normally processed at 165°C – I think some of them are getting closer to 150°C – we’re at 135°C to process that.

Figure 2. Dr. Ian Tevis, cofounder of Safi-Tech

MB: I think it’s safe to say that the reflow profile looks significantly different than that for SAC 305.

IT: Yeah, it’s a ramp-to-peak. We try to go as quickly as possible to that peak reflow temperature because that flux activity is always on, and when it’s always on, a liquid metal microcapsule can actually get joining at 20°C. It’s limited, but you can get a little joining and then that’s it. Then you’re done.

MB: Has the testing you’ve done to date been from boards that will run through convection reflow and, if so, was that nitrogen or just air environments? Or have you tried any other type, like vapor phase?

IT: The boards that we’re talking about for this thermal shock, they were put through a BGA rework station. We have a wonky process that involves printing solid SAC 305 microcapsules on a board, heat cycling the SAC 305 above its melting point, then cooling it to a lower temperature and then bringing a flux-dipped BGA in contact with the supercooled liquid SAC. It’s a couple extra steps to do it, where we’re doing flux dipping and heating and such. That system was originally done in air. Indium suggested we do it in nitrogen, and here’s the PPM that we should be looking at. And we did it in nitrogen, to great effect. It does help quite a bit, mainly because with the lower temperature processing of the alloy, you have more viscosity, you have less ability to wet and move, and so you want to limit that oxide formation as much as you can.

MB: You mentioned the test vehicle earlier and that there’s BGAs on it. What other parts are on it and was it designed just to look at the solderability of the platform, or were you also looking at the potential dispensing and other characteristics?

IT: The test vehicle was chosen to demonstrate all the parts, the printability of this material with the shell, to make sure that the shell isn’t disrupted; it’s the use of a flux, and to look at the soldered joint with these test vehicles have SAC 305 solder balls on them. They’re a great test to show because the SAC 305 ball, if it’s not melting, it won’t collapse. And you can see that clearly on the micrographs of the cross-sections, and you’re looking at IMC formation on our material, SAC 305 and the immersion silver FR-4.

If you have a thick intermetallic compound, five or more micrometers, you probably did that at a significantly higher temperature than 180C°. The basic science discussion at Safi-Tech is over. This is a real solder joint. It is continuous SAC 305 IMC formation. It survives thermal shock. Let’s work together to finish this and bring it to market.

MB: Andy, when did Safi-Tech first appear on your radar?

AM: Indium has been working with Safi-Tech for six years, but it was only about six months ago that we made a decision that there was something here, there was more signal than noise coming out of the data, and the potential applications for this also really started coming out there. Everyone is aware of the drive to use lower-energy reflow for cost savings as one major thing, but also a major push within heterogeneous integration, for example, is the use of step soldering and the overall thermal budget for the assembly processes. So you have a high-temperature assembly process, and a very low one – and then ultimately primarily caused by things like warpage and so on, you’re going to want something that may want to be as low temperature as possible. That’s something that the Safi-Tech technology really offers in a way that other materials absolutely do not have.

MB: Has Indium performed any in-house testing or with its customers of this solder yet?

AM: We done internal testing and had some very positive results, which again is one of the reasons why we are starting to be interested in working with the Safi-Tech team, because we see the feasibility of this in the real world.

MB: Are all the samples being made in Ames or has anybody else taken on responsibility?

IT: We make all the materials in Ames. That’s all the solder microcapsules and any of the alloys. We have equipment designed for each of the different temperature ranges to manufacture them and our goal as a startup is to manufacture the material, and we draw a lot here on the Iowa State campus. We draw a lot of the resources here from the other tools available, but also the people here are well known for metals technology.

MB: How is this stored?

IT: There’s a couple ways we store it. What’s nice about the technologies is that the shell or the microcapsule, they’re different, and you can freeze the core and you can melt the core And cool it back down into a supercooled liquid state. The process of heat cycling to recover the supercooled liquid state is called reconstitution. As long as that shell is intact, you can store it as a solid, and then get the liquid state back just by heat cycling. For example, bismuth-tin: We could freeze it in a -20°C freezer and then remelt it at 138°C and cool it back down to ambient, and 100% of those microcapsules are in the supercooled liquid state, which is nice for transportation and long-term storage. Once it’s in the liquid state, we store it under nitrogen under ambient temperature, or we store it in a refrigerator setting. We’re trying to prevent the nucleation of the metal inside, so you give it a little less energy to move around, it’s a little bit harder for that metal inside to freeze. We sometimes store it in a refrigerator for up to four months in the liquid state.

MB: When it’s stored in a refrigerator, would it be at typical temperatures or does it have to have its own refrigerator?

IT: We store it between 0° and 4°C. I think that’s one of the differentiators between us and a normal solder paste: We can’t quite get the -20°C storage temperatures for our products yet. That’s one of the things we’re working on. We know the cold chain and its importance in the solder paste world. Right now, it’s stored as a separate system; the particles stored in one container; and the base vehicle, whatever it be, is stored in another. Then they’re simply mixed right when they’re going to be used.

MB: What’s the process for mixing? With a typical jar of solder paste, you might stick a stick in there and swirl around a little bit.

IT: We have a process for mechanically activating or kind of squeezing them. That could be true if you’re mixing too. So, the mixing process is important. We typically will add small amounts at a time and then fold it in, trying to use the liquid to mix in the solder balls without applying too much shear. Once they’re coated in a liquid, then they can be really sheared, because once those particles can slip over each other, that kind of water balloon-like structure, that elastic shell on the surface of this squishy particle really prevents the metal from being sheared open during the process of mixing or printing.

MB: Ian, I know Safi-Tech is a startup, and you’re funded by grants from the Department of Energy and SEMI-FlexTech and at least one private equity group. Are there any other organizations or companies providing funding at this time?

IT: Those are the three main sources: A VC that specializes in this deep tech, new emerging technologies that come out that are trying to get over the valley of death, and there’s not a lot of organizations that fund in this particular space. The (US) government is one of them, and then the VCs are the next leg of that as they cross the valley of death. We’ve been very fortunate that SEMI-FlexTech, this private-public partnership, funded us for creating interconnects at PET-compatible temperatures for flexible hybrid electronics. That’s where that bismuth-tin product I discussed came from. That was an 18-month project funded by Safi-Tech and SEMI-FlexTech.

Right now, we’re working on a Department of Energy SBIR (Ed: SBIR stands for Small Business Innovation Research, a form of grant). Their high-energy physics has a need to replace bump bonding for their wafer-to-wafer to chip-to-wafer attach. They have these large formats, readout and sensor chips they use for high-energy physics like CERN and other places. It is difficult to assemble them because they’re so large, and get all of the little I/Os or sensor bits on the sides to connect. You get deflection on the device edge from dynamic warpage because these are like 50 micrometers, 100 micrometers thick, so they have a lot of deflection that can occur. We have a unique approach using microcapsules in self-assembly to put the microcapsules down and solder them at a much lower temperature where the chip, and the sensor are relatively planar to one another, so we limit head-in-pillow and the opens on the device edge.

Figure 3. Dr. Andy Mackie, principal engineer and manager, Indium Thermal Interface Materials Applications.

MB: Andy, in your long tenure in electronic materials, have you ever come across anything like this?

AM: It’s fascinating. Going back to my physical chemist days, it’s wonderful to see the nature of phase transition being absolutely turned on its head. I’ve seen this happen, for example, at IBM with its C4MP process – you see a subcooled alloy – you see these sort of little aliquots or little deposits of a subcooled tin-silver alloy, and they are cooled below the solidus point, but there’s still liquid and then you can watch them spontaneously solidify, and do that magic kind of phase transition, but at a temperature that is well away from what you normally expect from the standard thermodynamic solidus temperature and all this is allowed by the kinetics of the phase transition. To see this being implemented in solder itself is absolutely mind-blowing, and I recommend Safi-Tech’s video taking what appears to be a kind of a little solid grape, poking that with a microprobe, and this sort of grapelike object under the microscope, once its surface has been damaged and the solder leaks out a little bit, immediately solidifies. So it’s actually the nature of the physical chemistry of the shell itself that Ian was alluding to actually maintains that liquid phase when your standard textbooks tell you, “It’s below the solidus, it’s going to be solid.” It’s absolutely fascinating.

There’s fascination around the technology from a computer science point of view, but being able to turn that into something real and make money also excites my business brain.

MB: Let’s talk about the applications. This is currently getting funding from the US government. However, I would think that military applications are probably way down the list insofar as what would be the immediate end-product use.

IT: Yes, the requirements for MIL-spec and others are quite high for us to do. We are a startup and we have limited testing capabilities. We have Indium with a lot more capabilities to do the testing. You look forward toward those applications where they have a need for a lower-temperature solder. The military is excluded from the rules, and they can use that tin-lead, which is a great combination for solder and a great combination for supercooling. So there are opportunities there, but right now we’re looking for a really good entry-level application where our uniqueness is unchallenged, where there’s nothing else that can really do what we do, and the customers are in such a need and they’re willing to try a process change or something a little different to make it make their products work.

AM: We were just talking to one of our local universities about the increasing overlap between some of the applications in medical, such as cardiac monitoring, and people on the battlefield, so that the need for the troops in action to have their vital signs monitored at the same time. Clearly the kinds of stresses, 10,000G-type stresses, that a hypersonic missile would need to withstand, will necessitate a tin-lead joint or something like this, whereas some of these medical devices – and Ian already alluded to PET and maybe even lower-melting types of substrate – these medical-type devices are really necessitating low-temperature flexible substrates because the corollary to that is that it can’t go above 120°C, 100°C, 150°C, so you really are limited. For the military aspect to this, there is clearly an overlap between the needs in the medical industry for flexibility, conformance to body shapes, and so on, and the battlefield, and all these kinds of crossovers are occurring.

MB: Andy, I understand from Safi-Tech’s perspective why it would want to partner with a major solder company. What’s in it for Indium?

AM: For Indium, it is the opportunity to be in at the ground level with an exciting new technology which we believe is probably never going to replace the whole of SAC 305 or any of the large-scale solders, but with the emergence of these lower-temperature requirements, step soldering, flex, flex circuitry, and so on, and frankly the wide-scale promulgation of these, particularly with an aging population, should we say, necessity for that, we can see now real applications for these solders going forward.

We wanted to be in at the basement level with Safi-Tech, with which we’ve been working quietly for many years. We’re talking regularly to customers and equipment partners and so on to develop not just the materials for them, but also the processes that Ian’s talked about that go into this. We have the whole wonderful triangle of the material and the equipment partner and the process ready, and then we have the customer need all kind of set up there. We want to be ready so that, once the scale-up comes, we (can) provide the ability to scale these materials.

MB: The anticipation, then, is that Indium would actually get into the manufacturing?

AM: Absolutely, yes.

MB: Ian, Iowa has been ground zero for a few significant advancements in solder materials. Ames Laboratory, which is part of the Department of Energy and a partner with Iowa State University, developed and licensed one of the first tin- silver-copper solders to become mainstream in electronic soldering. I have to ask, what’s in the water there?

IT: (laughs) I know, I think there’s something special here. They’ve really built such a great environment for metals technology. One of the inventors of that (original SAC) alloy, Dr. Iver Anderson, is one of our advisors. He really works closely with my partner, Professor Martin Thuo, both at the university and at Ames Lab. We know how important it is for these metallurgical advances to continue and the technology we invented, Iver’s thesis was in supercooled metal alloys. This is a technology that has been there for a while. It was: How do we turn this into an actual material we can use?

MB: You have the ability to manufacture. You’re proving out the platform. You have a major vendor as a partner. Andy referenced scaling a little bit ago. What’s the next step?

IT: I think it’s really deciding where do we want to go. We have this platform, and it can be used in a lot of different ways, in many different applications. We’re a startup. I have precious few resources to bring a product to market. Indium is helping us with some of these customer interactions to ask the right questions, to say: “This is of interest to us and because of X,Y, and Z.” It’s like picking the target, and then customers have to touch it and try it, and then they have to lower their apprehension for it, then get it spec’d into what they’re building.

MB: Are the industry standards as written today open to accommodating this type of technology, or will there be need to change?

AM: This is another reason why this is a perfect storm of wonderful. The current version of J-STD-20 speaks to the temperatures to which a hierarchy of solders in a single assembly are going to be subject to. There’s a high temperature, a medium temperature and a low temperature, and there’s an ultra-low temperature, and this is something that’s actually falling out of the current version of J-STD-20, I think the F version of it.

The timing for this could not be better because it’s going back a little to those times of the tin-lead solders and bismuth-tin solders and saying: “We’ve got to have a hierarchy of solder, so we’ve got to have a solder with a melting point somewhere around that of tin-lead, which is around 183°C, but it can’t contain lead. What are the opportunities for this?” The next revision of J-STD-020 is going to include a three-tier system. Anyone who’s looking at how to qualify a material into this process is going to have a “lookup” table: “So we need to do this with this specific package size because it’s dealing mostly with the system-in-package type applications, heterogeneously integrated devices” and so on and so forth.

MB: I thought J-STD-020 was the component moisture sensitivity standard.

AM: That is absolutely correct, but it is so much more than that. Every customer that we talk to in system-in-package is asking: “What’s the maximum reflow temperature I’m allowed within this, based on this specification?” And yes, it’s moisture sensitivity, but it also as an adjunct to that, is now becoming this kind of stratification of the allowable maximum reflow temperature that, again, speaks to step soldering and the needs of heterogeneously integrated devices. •

Ed.: This transcript was adapted from a full interview for PCBChat.com. Safi-Tech’s lab is located at the Iowa State University Research Park in Ames, IA. For more information, visit safi-tech.com.

is president of PCEA (pcea.net); mike@pcea.net.

Press Releases

- 2026 IEEE Electronic Components and Technology Conference Student Innovation Challenge Pre-registration Deadline Extended to January 11, 2026

- PCBsync PCB Assembly Introduces Full-Scale Electronic Manufacturing Service

- Magic Leap Partners with Pegatron for AR Glasses Components Production

- TEXMAC/Takaya Appoints ARK Mfg. as New Rep in Arizona