Current Issue

Using Cross-Sectioning for PCB Assembly Qualification

While destructive, slicing can best x-ray for failure detection and analysis.

Cross-sectioning can be beneficial to printed circuit board assembly (PCBA) qualification as a means to understand process capability and identify potential design and manufacturing concerns. Cross-sectioning is a destructive method in which a PCBA is cut open to view the raw innerlayers, solder connections or internal component devices. The Benchmark Electronics Nashua, NH, division has a dedicated failure analysis and product assurance laboratory that performs cross-sectioning and many other analytical services for PCBA, electronics subassembly and systems. Onsite tools such as ion chromatography, SIR (surface insulation resistance) testing, dye and pry capability and electrical component failure analysis assist customers with PCBA qualifications and failure analysis work.

A key understanding of the assembly process is required to prepare the cross-section sample for high-magnification inspection. Knowing which reference designator locations and the direction the sample will be cut from the printed circuit assembly is important to prepare the cross-section piece for analysis. The next step is adding the sample to an acrylic potting agent; the potting substance will then be cured. Next is grinding the section in the cured potting material closer to the process target for analysis. A low grit sandpaper will be used to grind the sample down with a higher grit when approaching the target and polishing for inspection. The final step is to chemically etch the sample for high-magnification inspection and analysis.

The cross-section process requires a hands-on technique and an understanding of how the sample needs to be prepared for inspection. Cross-sectioning is a destructive process in which the assembly will not be salvageable or usable after the work is completed; if the sample is improperly ground, the desired information may be lost.

PCBA Qualification

The scope and detail of a PCBA qualification differs given technology, product lifecycle and overall end-product use and environment. As an example, some commercial electronics products will have a different PCBA qualification scope compared to a high-reliability medical or aerospace assembly. Cross-sectioning will benefit any electronics product by determining if the assembly meets IPC criteria by complementing the documented qualification and functional test process and acceptance plans.

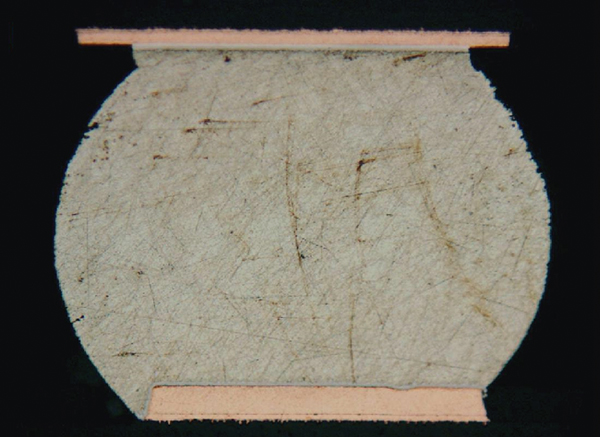

FIGURE 1 is a cross-section of a BGA. The cross-section can verify many aspects of the assembly process, including wetting, acceptable voiding, sphere uniformity, the presence or absence of solder fractures, and overall acceptability to IPC criteria. Under high magnification, the intermetallic layer can be verified to show proper formation and measure the thickness of the intermetallic between the BGA sphere and PCB pad.

Figure 1. BGA cross-section.

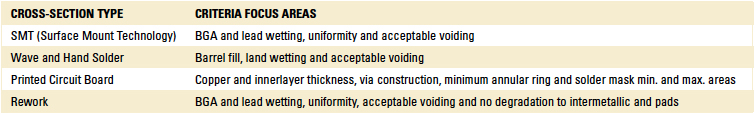

In addition to the BGA section above, any component package type and soldering technology (wave solder, hand solder, robotic soldering) can be cross-sectioned to ensure IPC criteria has been achieved. TABLE 1 details sample guidelines for potential locations and areas of focus. The areas of focus can be associated to inspection criteria for PCBAs and bare printed circuit boards.

Table 1. Cross-Section and Criteria Focus Guidelines

Analysis of the cross-section requires process understanding of PCB assembly, SMT, wave soldering, hand assembly and PCB construction. If a nonconformance is observed with the cross-section during high-magnification inspection, in-depth analysis may be required. One specific example of a potential nonconformance detected may be head-in-pillow (HiP) with a BGA. The potential cause may be associated to a component, PCB pad or solder paste; process experience will assist with the root cause analysis.

Additional Benefits

Many benefits exist for cross-sectioning other than for PCBA qualification, including detection and analysis of failures, which typical PCBA screening tools such as x-ray may not detect. With cross-sectioning, failure modes that are difficult to determine root causes for, such as BGA sphere micro cracks or separation, can be detected at the package or pad. The following is a sample of additional benefits:

- Solder quality or plating thickness, including wetting, voiding criteria and intermetallic thickness and construction on PCBs, assemblies or components.

- Solder paste qualification to introduce a new solder paste to the assembly process to complement other design of experiments (DoE) attributes.

- New process or technology qualification such as robotics soldering, new wave solder equipment or wave solder alloy introduction.

- PCB internal failures such as opens or shorts and component failures. Cross-section can detect micro cracks, innerlayer opens, or shorts when other tools may be inconclusive.

Conclusion

Cross-sectioning can be used as a tool to qualify printed circuit assemblies and complement a company’s new product introduction and qualification process. Additional budgeting may be required for the PCBA cost because after cross-sectioning, the assembly is not usable and is deemed scrap. In addition to the validation of the assembly process during qualification, cross-sectioning is a beneficial tool for failure and root cause analysis.

Acknowledgments

I would like to thank and acknowledge Paymon Adl-Zarabi at Benchmark Electronics Nashua, NH, division for his insight, assistance and contributions to this article.

is manufacturing staff engineer and environmental management representative, Benchmark Electronics (bench.com), and a contributing author to Green Electronics – Design and Manufacturing; scott.mazur@bench.com.

Press Releases

- AIM Solder Hires Francisco Rodriguez as Regional Sales Manager for Northeast Mexico

- The Test Connection, Inc. Adds Creative Electron Prime TruVision™ X-ray and CT System for Deeper Failure Analysis

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging

- ECIA’s February and Q1 Industry Pulse Surveys Show Positive Sales Confidence Dominating Every Sector of the Electronic Components Industry