High-Temperature Soldering of Through-Hole Connectors

Be sure to optimize the preheat to improve wetting.

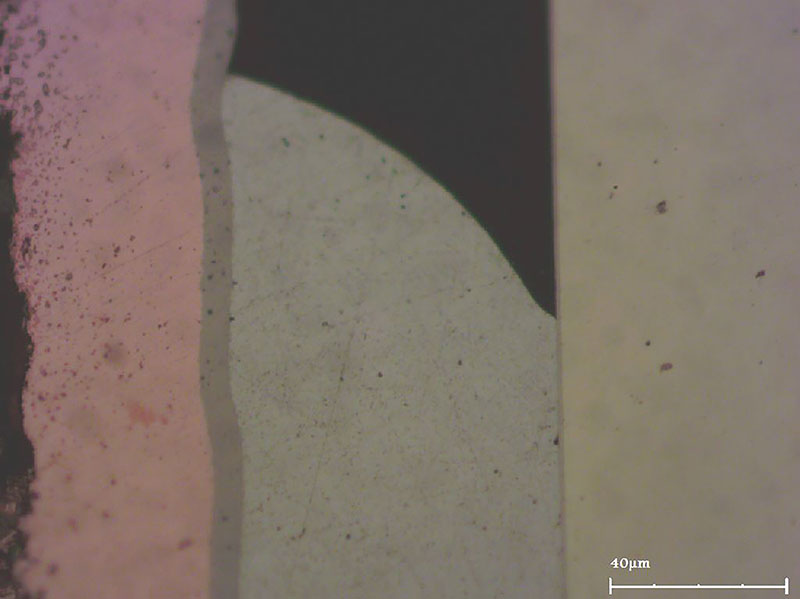

This month we we illustrate high-temperature soldering of through-hole connectors. In this case both the PCB nickel/gold surface and the tin surface of the pin were perfectly solderable. The time to preheat the board and connector before soldering was not optimized for robotic soldering, however. To obtain the correct process setting, balance all settings, but to increase throughput in an inline process using a robot, many applications require preheating. Robots are flexible, but an operator can see and judge the time required.

Figure 1. A mounted PTH connector.

Nitrogen used on robotic point soldering can improve wetting but more importantly increase preheat to the joint area. Soldering trials have shown it can increase throughput with small increases of flow rate. Another option is to have the waiting boards on the conveyor first pass over a preheater or through a heated tunnel.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.