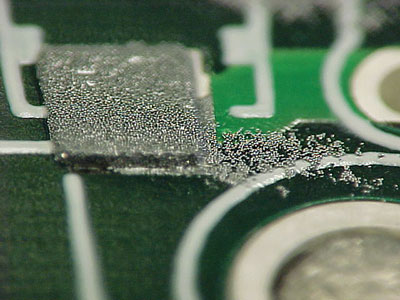

Solder Paste Migration

Are you vacuuming the right way?

This month we see a solder paste print deposit with what appears to be migration of paste particles away from the main pad. If this is just a one-off, a careful wipe with acotton bud would avoid an unnecessary wash-off and reprint. Ensure the PCB surface finish can withstand a wash-off process; some surface finishes don’t like it. Wash-off can affect wetting and final solderability.

A few reasons for this defect, each of which could be the root cause:

- Double printing or excess squeegee pressure

- Solder paste contamination on the bottom of the stencil from a previous print

- Misplaced or missing component

- Vacuum hold-down of PCBs during printing with exposed vias under BGAs.

Figure 1. Solder paste print with stray solder paste particles on the surface of the solder mask.

Figure 1. Solder paste print with stray solder paste particles on the surface of the solder mask.

The best example of this type of fault is due to the incorrect use of vacuum to hold boards flat during printing. I remember seeing my good friend Alan Hobby from DEK (now retired) demonstrating this during one of our workshops.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.