No-Clean Flux Residue

Improper reflow profiles make cleaning harder, if not impossible.

Improper reflow profiles make cleaning harder, if not impossible.

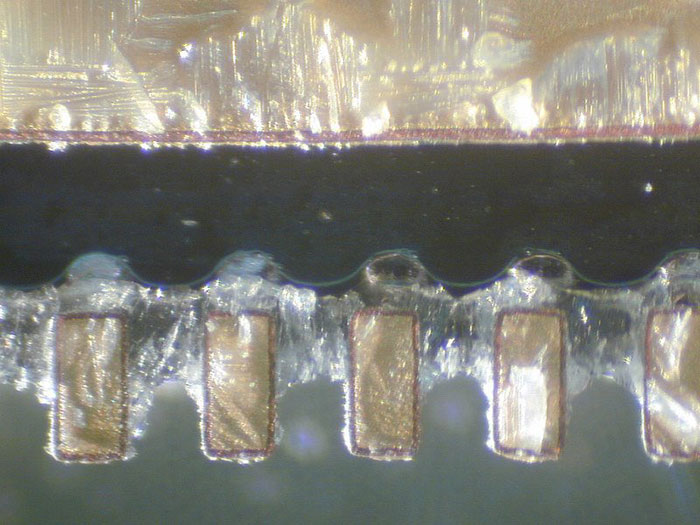

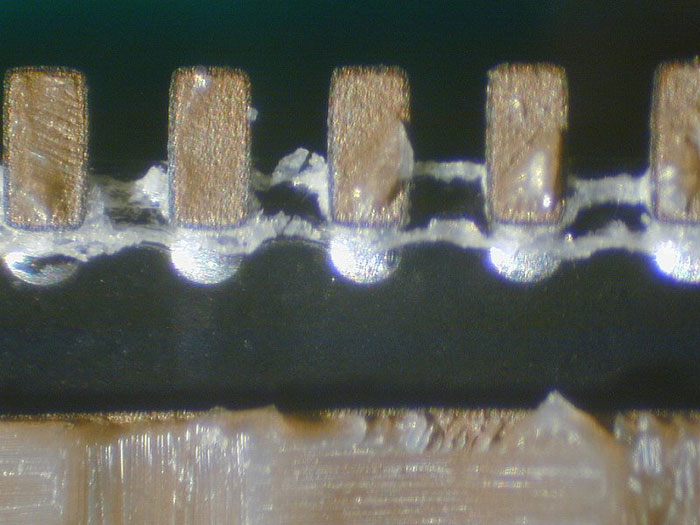

FIGURE 1a and 1b show QFN packages that have been reflow-soldered to boards, then mechanically removed in order to examine the flux residues under the body of the component and terminations. Many debates have been held on effective cleaning under this low-standoff package. It is clear in these examples that flux residues remain.

Experience shows that, with the correct paste reflow profile, flux residues can be cleaned. Still, flux residues must also be cleaned with the correct chemistry and cleaning process, else the results shown in Figures 1a and 1b are to be expected. The images show a combination of unsuccessful cleaning, practical solubility and white residues were not soluble in the cleaning process and remain on the parts and the board.

Figure 1. QFN package reflow-soldered to PCBs, then mechanically removed to show the flux residues.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.