Sulphur Corrosion on Solder Joints

Exposed copper coupled with silver final finish is causing opens.

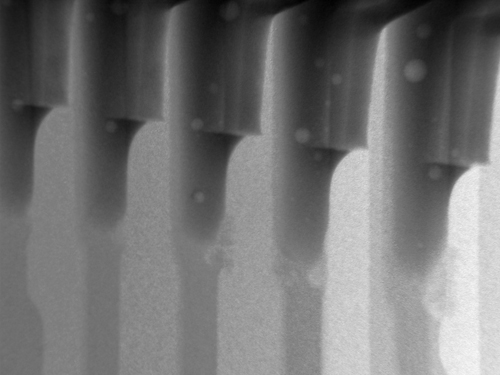

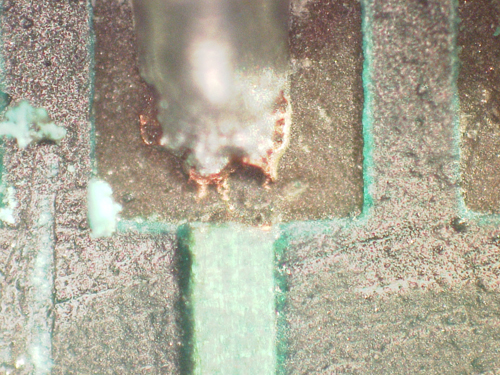

Figures 1 and 2 show two images of the same problem: one x-ray, the other optical. In both cases it’s the result of sulphur corrosion on the surface of copper and silver surfaces.

Both surfaces remain exposed after a soldering operation, and in the presence of sulphur, it is possible to witness corrosion. In time it can result in an open connection, as the figures show. Figure 1, taken on a Dage x-ray system, shows different degrees of corrosion on the tracking just below the solder joint fillet. In failure investigations it’s important to see and record as much as possible without change or damage to the sample. On one joint there was an open connection on this QFP device.

Figure 1. X-ray image of a QFP exhibiting sulphur corrosion, which can cause opens.

Figure 2. An optical image of the same issue, which is tied to exposed copper and silver PCB finish.

The optical image (Figure 2) illustrates the open circuit connections after the sulphur blooms have been brushed from the surface, revealing the extent of the copper reduction. This type of problem has been seen in industry many times, in the past most commonly on chip resistors where the presence of sulphur in the environment or in materials close to the surfaces has resulted in loss of continuity between the resistive element and the wraparound termination on the surface of the parts. It’s been seen in automotive and military products, even with the protection of conformal coating. Most recently the problems have been related to a combination of exposed copper and silver PCB finish, as shown in these examples.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the “Defect Video of the Month,” presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

Dr. Chris Hunt is with the National Physical Laboratory Industry and Innovation division (npl.co.uk); chris.hunt@npl.co.uk. His column appears monthly.