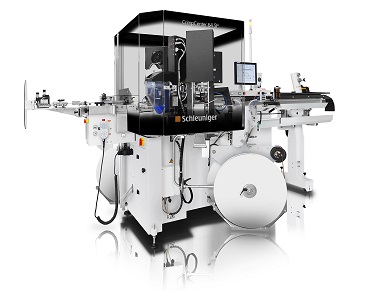

Schleuniger Introduces CrimpCenter 64 SP Crimping Machine

CrimpCenter 64 SP automatic crimping machine has dual quick-change system.

Can prepare new job while production is running, change applicators and terminals in 30 sec. and reportedly save more than 1 min. per terminal changeover compared to conventional methods. Offers application-specific default values for process parameters, automatic control of pneumatic pressure of feeding belts and gripper systems, straightening unit and roller design for thin cables. Includes deposit gripper system and integrated crimp-force monitoring for multiple stamped terminals, as well as split-cycle function. Optional sensor monitors stripping process in real time, detects contacts between stripping blade and wire and automatically finds best stripping parameters for wire to be processed. Software ensures traceable production quality, repeatability and monitoring of stripping results and seal positions. CFM 20 crimp-force monitoring system tracks signals during crimping process with sensor and compares them with reference signal. Can compare and monitor up to four signatures for multi-stamped terminal applications. Employs material change detection to register changeovers of wires, terminals or crimp applicators. Crimp-force monitoring guided feasibility study evaluates monitorability of solderless, electrical crimp connections and ensures reliability of monitoring parameters. Motorized measuring device determines pull-off-force values of crimp and ultrasonic welding connections. CHM measuring system is responsible for crimp-height measurement. Four processing stations can be installed simultaneously. Interfaces with MES. Signal light indicates current machine status and can be programmed according to customer requirements.

Schleuniger

schleuniger.com