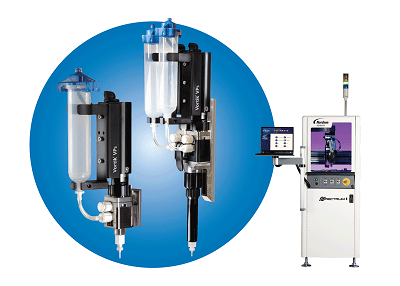

Nordson Asymtek Introduces Vortik Progressive Cavity Pumps

Vortik progressive cavity pumps have process controls for mass flow control and automated ratio control system for mixing two-component fluids.

VPs, VPm, and VPg series are based on general volume ranges. Each includes models for dispensing one-component (1K) and two-component (2K) fluids. ARC technology in Fluidmove software ensures accurate mixing ratios of 2K materials. Process control is done inside dispensing platform. Changes in speed or volumetric output are logged. Vortik VPs pump delivers low flow rates and small depositions of 1- and 2-component fluids, such as conductive epoxies, solder paste, and other adhesives used during electronics manufacturing for automotive, mobile devices, and MEMs. With a flow rate of 0.2µl per sec., VPs pump produces lines narrower than 300µm. Vortik VPm and VPg pumps dispense volumes from 2 to 400 µl/sec. for applications in electronics package assembly and automotive electronics.

Nordson Asymtek

Nordsonasymtek.com