Conformally Coated Chip Caps

While coatings are typically used on boards, some choose to coat components as well.

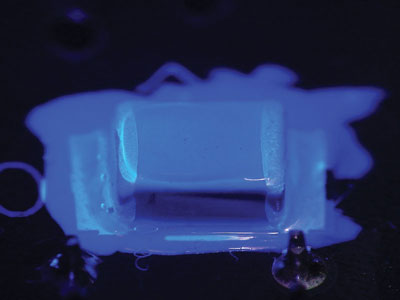

This month we show manual conformal coating on one component. One optical example is shown under normal lighting and then under UV light, to show the tracer added in coatings to allow easy manual or automatic inspection. This is not a defect. I asked if this was intended, however, as it was unusual.

Traditionally, coatings are used to protect circuit boards in humid environments and more so in condensing conditions to prevent corrosion. On some occasions design engineers also use coatings to provide that little stability.

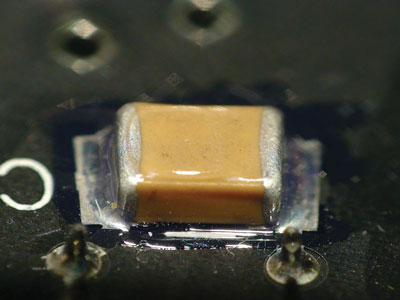

FIGURE 1 shows a chip component manually coated with conformal coating. It was a specific requirement of the design engineer that this part required coating.

Figure 1. A capacitor manually coated with conformal coating under normal lighting.

FIGURE 2 shows the capacitor under UV light. Manual coating has completely covered the part and the edges of the capacitor. It may not be pretty, but it is acceptable and met the design engineer’s requirement.

Figure 2. The same capacitor under UV light.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.

Press Releases

- Altus Partners with Sellectronics to Enhance Manufacturing Capabilities with PVA Delta 8 System

- ITW EAE Celebrates Major Milestone in Domestic Manufacturing Expansion

- Micro Technology Services Selects PBT Works CompaCLEAN III for Advanced PCB Cleaning Performance

- Indium Corp. is Electrifying the Future with Advanced Materials Solutions at Productronica