Inspecting Paste with X-Ray

Using x-ray in a nonstandard way is useful in process development.

Using x-ray in a nonstandard way is useful in process development.

Here are three different examples of paste after placement or prior to through-hole component insertion. The images shown here are not necessarily defects, and it may seem strange to use x-ray to inspect paste deposits after printing, but it can be very useful for in-process control and ideal for preproduction runs.

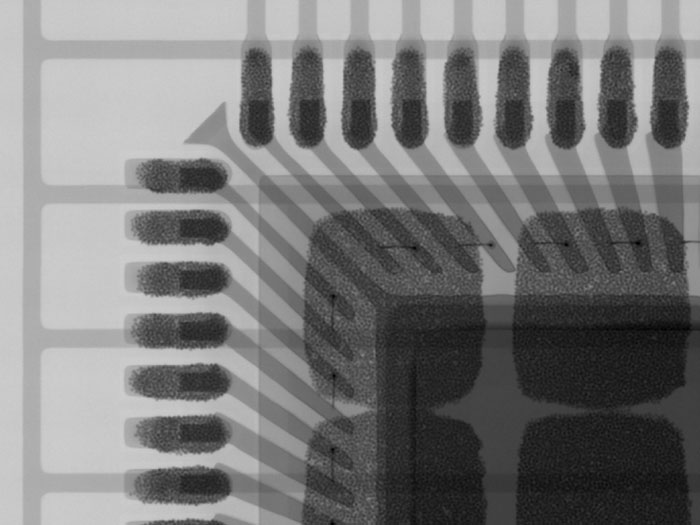

FIGURE 1 shows a QFN/LGA. In this case we are interested in the placement force and the degree of paste displacement on the center pad under the device. Normal practice is to look at the degree of paste variation between printing and placement. It’s even more important when there are multiple rows of outer terminations.

Figure 1. QFN/LGA with paste displacement.

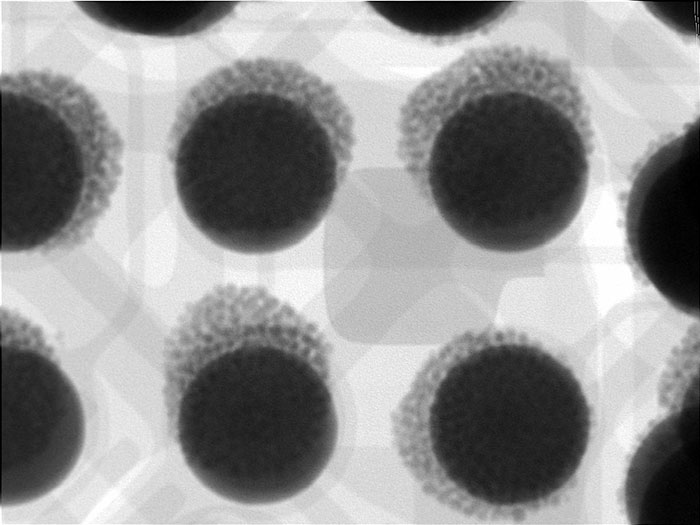

Monitoring paste variation on package-on-package (PoP) assembly can be beneficial during new product introduction (FIGURE 2). Normally the paste printed on the board can be confirmed by SPI, but paste applied by jetting or dipping on the second or third level of package assembly is a little more difficult. In the case of second generation PoP devices with through vias, the position of the paste between the balls can be assessed, or its misplacement on the sides of the vias. Lack of dip paste can lead to opens.

Figure 2. PoP assembly with paste adjacent to vias.

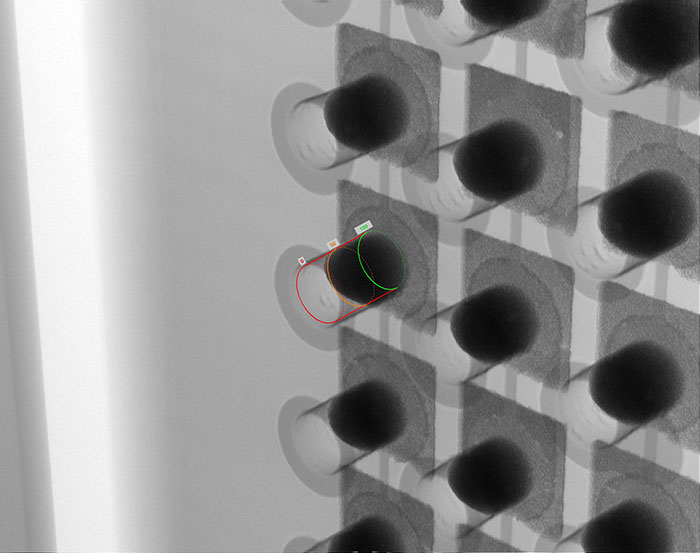

The image in FIGURE 3 is post-through-hole reflow or pin-in-hole reflow where paste is printed on the surface of the board and into the through-hole. It is easy to see and measure the paste filling the hole. It’s also possible to check paste displacement in the hole when components are inserted, as well as any displacement under a connector, which completely covers the paste on the topside.

Figure 3. A through-hole board with 50% hole fill as seen with x-ray.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.