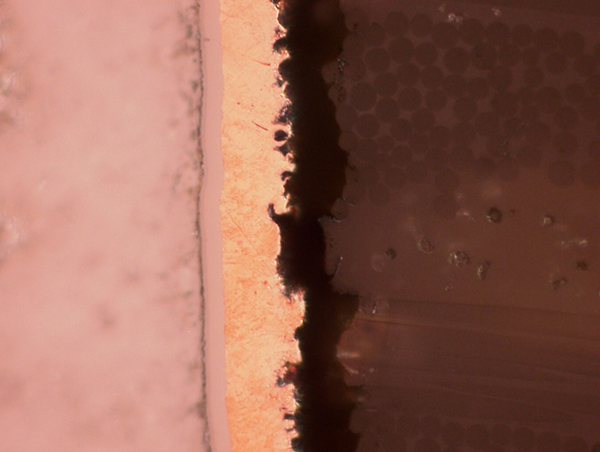

Copper Hole Wall Pull Away

Optimize the soldering parameters to resolve PTH separation.

If excessive heat or duration at elevated temperature is experienced during soldering, the copper barrel can pull away from the surface of the drilled fiberglass in a plated through-hole. This can occur where the adhesion of the copper to the drilled hole is poor during manufacture, but as shown in FIGURES 1 and 2, it can also be related to the soldering parameters used.

Figure 1. Incorrect soldering para-meters can cause PTH barrel separation.

Figure 2. Copper separation can reduce PTH pullout strength.

Some separation of the copper barrel can occur during temperature cycling of through-hole joints, but it is uncommon to see this cause an electrical failure. Selected areas of copper separation in the barrel can also lead to a reduction in through-hole pullout strength, but again not necessarily cause failures. In the case of the figures, further optimization of the soldering parameters should eliminate the copper separation.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is with the National Physical Laboratory Industry and Innovation division (npl.co.uk); chris.hunt@npl.co.uk. His column appears monthly.

Press Releases

- Altus Reports Growing Demand for Guidance on Convection Reflow Oven Specification

- Coherix Opens New Adhesive-Dispensing Vision Center in Europe

- Pan Pacific Strategic Electronics Symposium Program Finalized

- The Most Critical 2 Inches in SMT Manufacturing – When a Splice Fails, the Line Fails, Full Stop. Throughput and Yield Depend on One Overlooked Moment