Lighting the Wick

Capillary effect can thin conformal coating, but more material isn’t the answer.

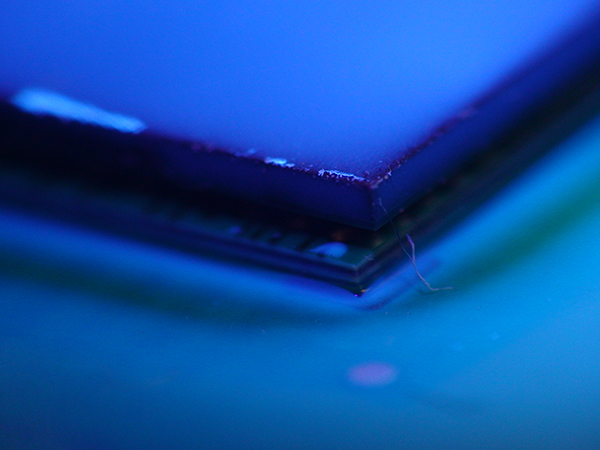

Conformal coating is gaining popularity to improve product protection and not only for high- reliability products. Mobile consumer products benefit from the protection, particularly around sensitive circuits and battery terminations. The example of a coating being inspected under a UV light (FIGURE 1) shows wicking resulting in local thinning of the coating. The coating is being drawn under the package due to capillary forces, which may not be desirable. The same problem often can be seen with gullwing quad-flat packs with a very large surface in contact with the PCB substrate. The result, as shown in Figure 1, is coating thickness is decreased around the edge of the part, a potential problem for leaded parts.

Figure 1. UV light reveals thinned conformal coating, the result of wicking.

When this problem occurs, the first thing to look at is changing the SG or solids content of the material used. Obviously, check the coating material regularly for changes. Making the change will decrease the loss of material under the package and provide a more reliable product than will a double coating. On many components, excessive coating under parts can lead to problems during rework and component removal. Equally, if the coating material has a large expansion rate during thermal cycling, it will rip the solder joints from the board surface, which has been known to happen.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the “Defect Video of the Month,” presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is with the National Physical Laboratory Industry and Innovation division (npl.co.uk); chris.hunt@npl.co.uk. His column appears monthly.