SPC May Have the Solution

Isolating tolerance issues is simplified by good software.

Amid all the printer demands for speed, throughput, accuracy and transfer efficiency, engineers and operators can lose sight of the fundamentals. In other words, troubleshooting the solution to a printing challenge isn’t always complex. There’s no doubt miniaturization has made the job of the printer more demanding and its success all the more critical. But, even with this reality, the answer to a print process conundrum is often a basic, simple one revealed through on-board SPC tools.

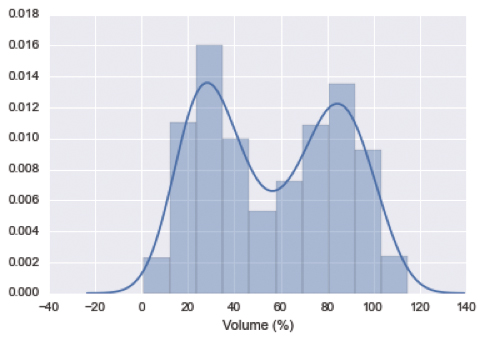

SPC is used to measure, map and analyze all types of printer data, and turning to this invaluable resource as the first step may save huge amounts of time, yield loss and headaches! In fact, some recent work in our company labs helped underscore this reality. Our team was doing work on heavily routed production boards arranged in a four-up panel with challenging component spacing and deposit areas that included metric 0402s and 0.4mm CSPs. We could achieve alignment on one panel, but then the other three would be out of alignment. The data were non-normal, and there were sub-processes within the data (FIGURE 1).

Figure 1. Data showing non-normal data set.

We switched on-board stretch within the SPC tool and ran a new batch of boards through the printer to compare it to the first group of boards to more fully understand any variation. This function within SPC revealed there was quite a bit of PCB stretch and a significant data set disparity between the boards. With four arrays in the panel and the boards out of tolerance, each panel needed to be treated as an individual process because the stretch was that extreme. By using the SPC and executing some fiducial captures, our team was able to isolate the issue, understand the boards were out of spec and resolve the problem. FR-4 boards will never be perfectly aligned, but they should be within tolerance, and these most certainly were not! (For more on managing board stretch issues, read my column from June 2013.)

Another useful function within SPC is the ability to map and measure temperature and humidity. As solder paste materials continue to reduce in grain size, the finer packing density makes them behave a bit differently. In my experience, the Type 4.5 and Type 5 pastes tend to be more susceptible to environmental changes, including the environment within the printer. If the temperature within the machine becomes too hot, one might start to see printing issues like bridging and, further down the line, reflow challenges due to solvent loss from excessive heat. Tolerances for temperature and humidity can be integrated into SPC so that if these factors start to go out of control, a warning is issued to the operator. Some machines have better heat management than others, and being able to capture, record and analyze the conditions within the printer helps to avoid potential issues.

Understanding the pitfalls associated with heat and humidity, one feature to look for in printers is efficient motors that effectively manage energy consumption. Platform design should incorporate proper venting, streamlined cables and compact designs with more gaps to permit air and space within the inner workings of the machine. This is critical. Machines that can’t get rid of the heat often have what I refer to as “thermal runaway,” which can escalate into an almost uncontrollable vicious cycle. If a printer has very large motors and internal systems that generate a lot of heat, the process can begin to move out of control. To correct the issue, the operator will increase cleaning frequency, but the large motor used to run the understencil cleaner vacuum pump elevates the machine temperature even more. In this case, the SPC may warn the machine is out of temperature range, but the remedy is often downtime to permit ample cooling. (As a side note, when evaluating new machines, make sure production testing – not a simple demo – is undertaken to evaluate heat management. It can be the difference between an in-control or out-of-control process.)

Indeed, there are so many variables in the printing process that challenges may, at times, be difficult to isolate. Powerful data tools like SPC should be used as a matter of course to better understand the process, its variables and to develop the best solution. As we move toward higher densities and finer pitches, printing issues certainly can be complex. However, tapping into SPC functionality may reveal the problem lies with something as simple as out-of-tolerance boards or the internal printer environment.

is global applied process engineering manager at ASM Assembly Systems, Printing Solutions Division (asmpt.com); clive.ashmore@asmpt.com. His column appears bimonthly.