LGA/QFN Solderability

Good design rules and assembly processes will result in high soldering yields.

LGA/QFN solderability can be a challenge, and with an increasing number of components produced in this format, care needs to be taken to find a suitable test method. In reality we mainly focus on the bottom surfaces of the packages, as the side sections of the lead frame are often not solderable.

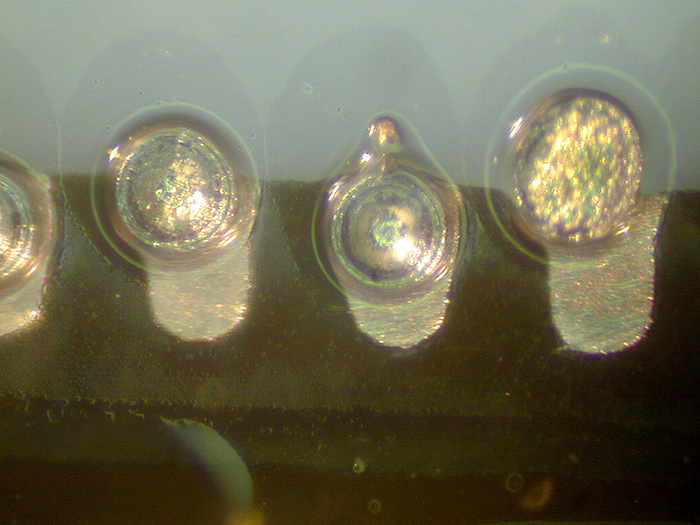

FIGURE 1 shows a package reflowed on a glass slide with the same solder paste used in production and the same stencil aperture design used for assembly.

Clearly the wetting viewed through the glass is very poor. This would result in component float and open connections during assembly if the parts were used in production. This type of simple solderability test is practical for the shop floor or for researchers but does not provide the quantitative measurements suppliers want to see when faced with a part being rejected.

Figure 1. A solderability test using a glass slide (here) is inferior to wetting balance for generating quantitative measurements.

In this case, the wetting balance is the ideal solution for testing. It’s previously been demonstrated in our failure analysis workshops at NPL how the test is performed with QFN/LGA packages. Parts are mounted at 45˚ to the solder globule to avoid the nonwettable termination or body contacting the solder.

As this package is much cheaper to produce, lighter and gives the opportunity for simple cooling, more of these packages will be used as alternatives for QFP and SOIC packages in the future. Through good design rules and assembly process optimization, the soldering yields can be very high.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the “Defect Video of the Month,” presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is with the National Physical Laboratory Industry and Innovation division (npl.co.uk); chris.hunt@npl.co.uk. His column appears monthly.