Solder Fatigue Led to AirAsia Crash, Investigators Say

SURABAYA, INDONESIA -- The AirAsia crash that led to the death of all 162 aboard last year was triggered by cracked solder joints on the plane's rudder control warning system, Indonesia's National Transportation Safety Committee said today.

The pilots of the Airbus A320 lost control of the plane, which rolled and then ultimately fell from the sky in a storm last Dec. 28.

While pilot error was partly to blame, the NTSC report said, the warning system failure might have misled the pilot. "The degraded performance and ambiguous commands might have decreased the SIC's (co-pilot) situational awareness and he did not react appropriately in this complex emergency resulting in the aircraft becoming upset."

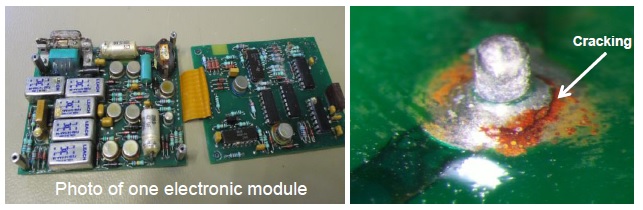

The report cited solder fatigue due to thermal cycling of the rudder travel limiter unit (RTLU). The rudder limiter system limits rudder travel at high speeds in order to prevent rudder/stabilizer overload. The system is controlled by an electric actuator which blocks rudder travel according to indicated airspeed.

Examination of the RTLU post-crash concluded that the failure of the unit was caused by cracked soldering of the electronic module of both channel A and B as result of the thermal cycles associated to ON /OFF power and ground/flight conditions and generated a fatigue phenomenon of the soldering, the report indicated. The crack of the soldering electronic module resulted in intermittent failure of the RTLU.

According to investigators who studied the flight's "black box" records, the plane pitched 44° at its highest angle, stalled, and rolled 104° on its left wing. According to the report, the aircraft then lost altitude with a descent rate of up to 20,000 ft. per minute as it fell from 38,500 ft. to 29,000 ft. altitude, at which point the wings leveled but the angle of attack (pitch) remained at approximately 40° up and the plane remained stalled. The aircraft continued to lose altitude at an average rate of 12,000 ft. per minute until it crashed into the Java Sea.

According to the NTSC report, the rudder control system had failed almost two dozen times in the year before the crash. Maintenance records indicated the rudder problem's frequency had been increasing, and the malfunction, caused by the cracked joint on a circuit board, occurred nine times in December alone.