Was RoHS Worth It?

Ten years after the controversial mandate to ban lead went into effect, those on the front line of the switch reflect on what was learned.

“Using the equipment and processes that have the least impact is always the best science … to wait until there is enough toxicity evidence is too late. Good prevention is always the right approach.” – Dr. Jennie Hwang

The Restriction of Hazardous Substances Directive 2002/95/EC took effect on July 1, 2006. In the 10 years that have followed, perhaps no single development since the adoption of surface mount has had such a dramatic and widespread effect on the electronics design, fabrication and assembly industry.

Now known as RoHS 1 (a follow-up edict was issued in January 2013), the directive restricted the use of certain substances deemed to be hazardous in electrical and electronic equipment. While 10 elements in all were singled out, it was the ban on lead that touched off furious debate, not to mention angst, and led to fundamental changes in component assembly and processing – the effects of which are still being dealt with today.

The push to lead-free started much earlier, of course. Some credit its genesis to the US’s decision in the 1970s to ban lead from paint and, later, gasoline. In 1991, the US Senate proposed the Reid Bill (later modified in 1993), which proposed a ban on all lead-bearing alloys. It failed, but the movement spurred efforts abroad, particularly in Europe and Japan.

On this, the 10-year anniversary of the law, PCD&F/CIRCUITS ASSEMBLY looks back at the industry as it existed then, and spoke with those who were on the front line of the lead-free movement.

Karl Seelig (AIM vice president of technology, inventor of Castin tin-silver-antimony-copper alloy):

Lead use was doomed from the time they took it out of gas. Then in the mid-80’s plumbing started eliminating it.

At the time we were developing plumbing alloys. Castin was a spinoff of work done for the plumbing industry. The Japanese led the early insurgence into lead-free. They actually suffered some of the mistakes of lead-free in electronics. I gave a seminar in the late 1980s and predicted it would happen: that there was a lot of lead-free developing going on.

Jim McElroy (executive director, International Electronics Manufacturing Institute):

I thought they were crazy. I got the feeling people didn’t appreciate how difficult it was going to be. There were a lot of skeptics from the beginning: Why are we doing this? Can we fight it? People had 50 years’ experience with tin-lead, and the implications that lead was leaching into the soils were overblown.

Dr. Richard Coyle (Nokia Bell Labs Reliability Engineering CMTS; ex chair, INEMI Tin Whiskers Users Group)

I thought it would affect consumer products immediately but perhaps never affect the products of telecom and other high-reliability end-users. At Lucent we had participated in Pb-free solder evaluations starting as far back as 1995 in the NCMS project and 2001 in the first iNEMI Pb-free solder project. Those results and other research projects worldwide had exposed many technical challenges and obstacles. Those obstacles created strong support for continuation of lead in solder exemption.

Paul Vianco (Distinguished Member Technical Staff, Sandia National Laboratories):

We probably realized with the NCMS Lead-Free Solder Project as it drew to a close in the late 1990s that this was a doable technology and wasn’t going to be as earth-shattering as everyone thought, technically speaking.

Carol Handwerker (chief, Metallurgy Division, National Institute of Standards and Technology):

There was legislation – the Reid Bill – to ban lead in the US. The NCMS formed a big project; the Reid Bill was defeated, and we looked around and said, “Well, there’s no threat, but this is not going away.” We laid out all our results and made recommendations and presented them to the (electronics) community in 1997.

Tetsuro Nishimura (Nihon Superior president and CEO; inventor of Sn100C tin-nickel solder):

At the time no one understood lead-free. “Lead-free? What is that?” they would say. Panasonic said, “Maybe in the future, no one will use lead.” We were incredulous. Our response was, “What?” So we started with tin. We heard from Iowa State University about the SAC (tin-silver-copper) system. We visited their lab in 1997 or 1998. This was about 10 years before RoHS. We had introduced tin-silver or silver-antimony, but it didn’t work well for less-expensive PCBs. It was hard to study lead-free in production, when every hour you have 200 to 300 PCBs running through.

Paul Vianco: At that point the fervor of the activity kind of leveled off, and the universities became involved in the R&D part of lead-free electronics. The electronics industry began to change too. We (the US and Europe) went offshore to the Pacific Rim. A lot of the steady progress became rapid progress, as offshore EMS providers decided they wanted to be lead-free and wanted the green technologies, and to begin to market them.

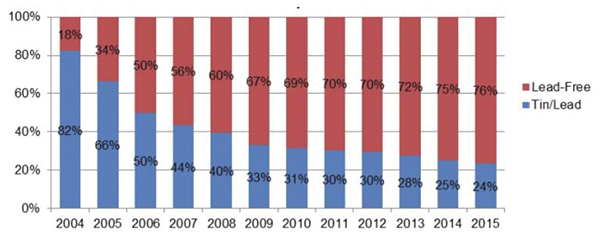

Figure 1. Solder paste delivery ratio, leaded and lead-free.(source: IPC)

The Race for a Substitute

Carol Handwerker: There’s no element in the table of elements that behaves like lead, except cadmium, which is even more toxic.

The NCMS group started with 76 alloys. We did manufacturing and reliability trials on seven, including tin-lead as a baseline. The group established a design matrix to establish which alloys to look at. We had down-selection criteria and design criteria. NIST did a complete analysis of the binary and ternary systems being considered so we could present the characteristics of the systems to the down-selection team, which I was on with Jasbir Bath and Edwin Bradley. About 100 people weighed in on it.

Paul Vianco: We tested Castin, the Sandia alloy (tin-silver-bismuth ternary), and an alloy in collaboration with Indium Corp., a heavy indium alloy. We performed these studies in a partnership with the AT&T Engineering Research Center in Princeton, New Jersey. That was a gem; those folks were the best in the business in terms of research-to-development-to-application. Engineers included Dr. Iris Artaki, George Wenger and Dr. Urmi Ray, to name just a few. We looked at tin-antimony – a plumbing solder standard – tin-silver eutectic that was used as a high-end plumbing solder, and also the low-melting temperature: eutectic tin-bismuth and eutectic indium-tin. We built a lot of prototype boards with those solders and thermal-cycled them. A lot of that was to investigate the effects of indium. And it was doable.

Iver Anderson (senior metallurgist, Ames Laboratory; adjunct professor, materials science and engineering, Iowa State University; holder of 36 patents):

The first thing they thought was there’s been a decade since 1998-99 about lead-free and what one to choose and that a couple had patents. We had a patent in 1996. There was one from iNEMI. Senju’s came in later than ours, but their composition boundaries came up against the boundaries of ours. (Ed.: The Ames patent covers any alloy with 3.5 to 7.7% silver and 1 to 4% copper; the Senju alloy is Sn3.5Ag0.75Cu.)

Dave Hillman (metallurgist, Rockwell Collins fellow: materials & process engineer; subject matter expert for the Lead-free Manhattan Project; chairman of the IPC J-STD-002 Solderability task group):

They found the win-win, which is good because patent fights aren’t good for the industry.

Iver Anderson: That opened up Japan’s consumer electronics business to the world. By in 2000, they had done a commercialization effect to the world.

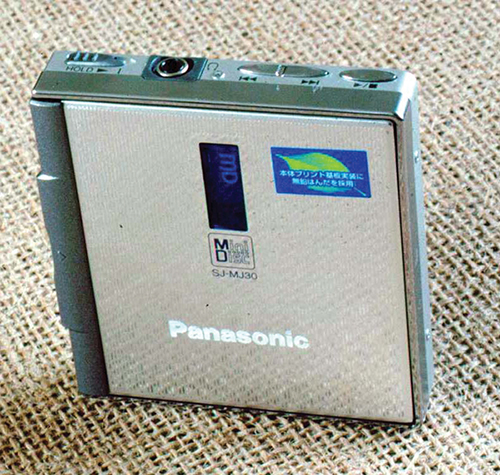

Dave Hillman: Japan looked at a heavy bismuth, which worked in white goods. I remember the green leaf sticker they put on products. That green leaf sticker was worth a 10% increase in market share.

Iver Anderson: I went to Japan and spoke to a gathering of 200 to 300 engineers who only spoke Japanese. You choose your words very carefully. I think they were auditing our alloy and what it could do, especially for composition.

Tetsuro Nishimura: I’m a metallurgist, so I was looking for a less expensive alternative to SAC because the cost was three to four times that of tin-lead. I studied a tin-zinc system, but it wasn’t good for soldering. I tried a tin-nickel-X system; that was the beginning of Sn100C. That was 1998. After I introduced Sn100C, my customers started to use lead-free around 2000. That was the start in Japan. RoHS was a requirement from the EU, so it wasn’t a “must.” But we still didn’t know what would happen. We had no information at the time.

Dave Hillman: We had finished the NCMS study in 1998. The high-temperature stuff was in its second phase.

Iver Anderson: Allan Gickler of Johnson Manufacturing was the first licensee, around 1997 or 1998. He was my mentor in electronics assembly. Going from a researcher in the lab to working on a problem...

Dave Hillman: The thing is, it wasn’t a problem…

Iver Anderson: In 1999, IPC held a meeting in Minneapolis. I still have the book on my shelf. It was like a professional wrestling match. That’s when the iNEMI 396 SAC alloy was proposed. We were gathered in the committee meeting. It was probably 300 people. We were deciding on alloys to go into round-robin testing.

Carol Handwerker: There were some discrepancies in Iver’s phase change diagram. This was May 1999. We had to make a decision by November 1999, and we at NIST had to drop everything to do a phase diagram of the SnAgCu alloy. Iver and I went head to head at the IPC meeting over the data. Iver’s patent held, but the composition of the joint that he patented allowed everyone to say, “Let’s support Iver’s patent.” But it was important to figure out the composition of the solder that we needed that had the lowest melting point. Iver said, “Yep, that’s right.” So we came up with the first alloy.

Iver Anderson: Over time some high-profile solutions allowed RoHS to go forward.

Figure 2. Once marketing took over, lead-free labels like this one for EU RoHS compliant product proliferated.

Why SAC Won Out

Kay Nimmo (International Tin Research Institute environmental affairs manager):

Discussion about the challenges and what could go wrong was the focus of attention, instead of finding a good solution. There was a lot of debate about how complicated it would be.

Dave Hillman: Industry-wide we disagreed. Why should I not manage the use of an element? The periodic table is only so big. If we manage things instead of eliminating them, we are better off. Time will tell if we’ve reduced them further than we’d like. That was the first impression. RoHS wasn’t going to work until WEEE was added. There’s a process there. RoHS said, “You’ve got this window of time where you have to do all this testing.” That’s where our industry rose up.

Kay Nimmo: We tested many different things with all kinds of exotic ingredients.

Dave Hillman: People were comfortable using tin systems and copper systems. SAC was comfortable. You migrate to your simplest system.

Carol Handwerker: NIST looked at SnAg, SnAgCu, and SnAgBi. We were asked about reducing the silver content from 3.9 to 3.0. Alan Rae and I wrote an opinion piece for CIRCUITS ASSEMBLY that said 3.0 should be fine.

Richard Coyle: For those of us still using through-hole mounting, copper erosion of vias during wave soldering presented a challenge. We also spent time on processes to mitigate tin whiskers, which still gets a lot of publicity today. We found the higher silver alloys were of greatest interest to us to meet our requirements for thermal fatigue resistance.

Dave Hillman: As an assembler, I need that alloy to work a certain way. We lost that with eutectic tin-lead, but SAC was close. Tin-silver was just a little too high of a melting point at 221°C, but everything else worked. But the price was a limiter. SAC 396 was too much. SAC 305 was too much.

Iver Anderson: The melting temperature was the first discriminator. Ours came in at 217°C, and we were doing handsprings. Chad Miller came running to me with the results and said, “Look at this.” That was a big day.

Dave Hillman: Fred Morris was looking at micro structures. I said, “Dammit, I just wanted an alloy that works.” In the end we found that middle ground. I remember automotive getting into it. They had the volume. They had the money. They can go further than the rest of us.

Iver Anderson: Ford was doing lead-free before it was sexy, but it had no temperature limits.

Dave Hillman: Today, the automotive guys probably understand where SAC 305 can go. They are pushing and trying to find the next solution.

Iver Anderson: We are looking fiercely at solid 100% single-phase intermetallic.

Tetsuro Nishimura: Twenty-four percent still use tin-lead right now. It’s not so easy to change to lead-free. Power companies, train systems, vehicles, military, medical: One failure and people say you may have tin whiskers or tin pest.

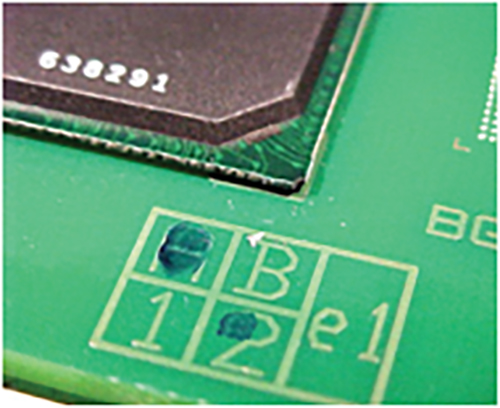

Figure 3. Different organizations proposed various board markings to designate the solder type. E1 represented SAC alloy. (source: UK Smart Group).

Environmental, Not Political

Iver Anderson: (Going lead-free) was an environmental issue. I remember a Norwegian presenter at an IPC meeting in 1999 who gave the best talk. It was on water quality.

Tetsuro Nishimura: It was the EU requirement. We still had questions, but we had to change. Everyone said “green.” But in the beginning it was a political issue.

Paul Vianco: There really was a lot of environmental pressure occurring in Europe at that time. Greenpeace was really very strong in Europe.

Karl Seelig: RoHS was being pushed by environmental groups mainly because of the fear of landfill contamination of drinking water because we were going toward disposable electronics.

Dave Hillman: They didn’t have a water problem with tin-lead. But to be fair, we didn’t have 400 million cellphones going into landfills.

Iver Anderson: That’s why Japan went first. With their population density, they have to live right next to landfills.

Dave Hillman: There are no papers that said that happened. In the end, though, it probably was the right idea. We should be managing (lead).

Jim McElroy: Even though it wasn’t dictated in the US, most people felt it was something (the US) had to do so we could sell product unrestricted across the world.

Kay Nimmo: We had done a lot of work and had a lot of cooperation with the Japanese, and it was clear lead-free was going to work. That’s when we knew there wasn’t going to be any going back, at least for consumer electronics. That was before the legislation was finalized.

Figure 4. Panasonic was among the Japanese OEMs that used a green leaf to designate lead-free product.

The Switchover

Tetsuro Nishimura: Around July 2005, people tried to change to lead-free. They needed some time to make the change.

Dave Hillman: It was going into effect in the consumer market. IPC wasn’t going to step into it, but that’s when we figured out we all use the same supply base. With RoHS they under-calculated what that supply chain does. Once one went, they had to make the choice.

Iver Anderson: All of a sudden, a new joining alloy was going to be introduced that didn’t have enough testing.

Dave Hillman: With the NCMS study, everyone said, “We are okay. Nothing works better than tin-lead.” But the rest of the world didn’t read that.

Tetsuro Nishimura: Japan is always looking for “green.” We had the responsibility to change ourselves to get others to use Japanese products.

Richard Coyle: We realized the difficulty obtaining tin-lead components was going to drive the transition to Pb-free.

Was it Worth It?

Karl Seelig: It’s driven up the cost of manufacturing. It’s changed everything about the process. How to weigh that against the potential environmental risks that were never proven? We’re still developing alloys; a lot of that has been for high reliability.

The learning has been going on since the 1990s, and we still don’t have a complete handle on it. It’s been a logarithmic increase in knowledge. I thought it would take off earlier – by the late 1990s.

Jim McElroy: iNEMI as an organization learned a lot about pulling people together and seeing the benefits of working together. This really helped us hone our process. And we did so many projects in this space. The fact that so many people had to do it made it noncompetitive; people had to work on it without worrying about the competitive aspects. It made us better. We still benefit from that today. One of the things we struggle with is taking too much time to form projects. We figured out ways to accelerate that, to get people to work together and trust each other. That’s a positive for everyone.

Tetsuro Nishimura: Before lead-free, I was always touching lead powder. It is so poisonous – everyone says chromium or mercury – but lead is very, very toxic. I was touching and breathing the substance every day. People said, “Tin-silver is no good. Go home.” But finally, I achieved it. We have many supporters now in the world. I’m still helping people learn how to do it.

Kay Nimmo: There was always this debate – should we use this alloy or that alloy – but there were always some alloys that were better for this or better for that (use).

Paul Vianco: It got us off the tin-lead bandwagon. When we started with lead-free, the guiding impetus was one universal alloy. And what happened in parallel was this explosion in electronics technology – the cellphone, laptops – and it kind of took the leash off, and folks said, “Maybe we can make better products if we aren’t tied to one material.” We got rid of the tin-lead leash.

Carol Handwerker: It was absolutely worth it. There wasn’t a drop-in replacement, but for some components lead-free is a lot better than tin-lead. Also, the technology changes a lot. The needs change quickly. People have gone to higher Tg boards. They probably would have gone to them eventually. It opened up a willingness to change material sets. It also demonstrates that when the community got together and was asked to basically make a change, they could do it. It was incredibly powerful. Likewise, when they got rid of CFCs, that was just for cleaning. This affected the entire industry.

Iver Anderson: You could say RoHS banning electronics really is a glimpse of the future. Because it won’t be the last time.

Carol Handwerker: It was really important to move to lead-free because of the recycling and lead contamination in the third world. If we hadn’t done it then, we would be doing it now. It actually has changed the way the people in the developing nations are being exposed to toxins.

Richard Coyle: We have an obligation to be responsible for the products we make and the impact they have.

Paul Vianco: It made us look at the rest of the solder joint as a system. Now they look at the strength of the solder as not being the only relevant parameter. For example, if we make the solder too strong, we force another failure mode like pad crater or break the BGA. In the end, lead-free opened up a lot of folks to the technology, not the art, of solder interconnections. New avenues have been explored that have directly resulted in a lot of the products that are pretty mainstream right now.

Dave Hillman: People look at materials differently because they have to reuse them. For all the insanity, some good things came out of it. Now recycling is normal.

Iver Anderson: The loop is closing. I have students who want to look at mining waste because recycling is how we’ll still have these materials. The Earth’s crust isn’t abundant with these materials.

Dave Hillman: That’s where the environmental sustainment degree came from.

Iver Anderson: The planet is an experiment. You can’t stop it. It’s about watching and waiting and seeing if you got it right.

is editor in chief of PCD&F/CIRCUITS ASSEMBLY; mbuetow@upmediagroup.com.

Join the discussion on this topic here.