A Robust Process Solution for Shield Edge Interconnect

Processing the PCB through underfill before placing the RF shield maximizes PCB real estate.

Numerous regulations enacted by agencies including the Federal Communications Commission, NEPA (National Environmental Policy Act of 1969) and OSHA limit emission of RF signals from a device. In the past, this was addressed via metal shielding in the form of soldered perforated metal cans and metallic fences, or plated gaskets with EMI covers. High-density packaging on smaller PCB real estate has driven OEMs to look for PCB edges as a potential area for shield placement. One approach has been to “think in 3D” in terms of the attachment area by routing copper traces along the outer edge of the PCB, a process known as Shield Edge Interconnect (SEI). SEI optimizes PCB real estate and provides added space on the PCB for additional components that will provide added functionality at lower cost, with components located 300 to 400µm away from the edge pad. An innovative new approach to SEI uses precision automated solder paste dispensing for SMT RF shield attachment. The process requires high-precision dispensing capability enabled by specific hardware (dispenser and pump), machine vision and software configurations. A singular advantage of this approach is that it enables underfill routines to be performed before placing the shield cans onto the PCB, rather than through perforations in the shield, as designs traditionally required.

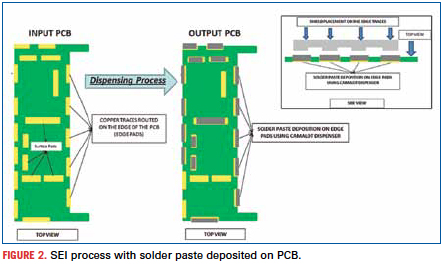

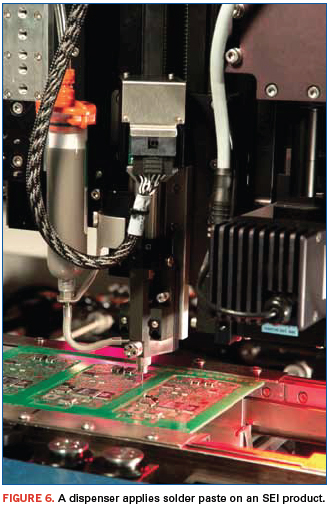

This new SMT process has been demonstrated to facilitate new space-saving attachment designs, while creating a robust soldered connection for SEI along the vertical surface of the outer edge of the PCB. Solder paste is dispensed onto the bare copper pads of the PCB along the traces or the perimeter where the shield will be placed. Here, the authors describe the process steps using dispensing for SEI.

Current shield placement techniques. Shield attachment to date has involved either of two methods. In the first method, a “metallic fence” is formed around the perimeter of the area to be shielded. Then a spring-loaded “metallic lid” is snapped over the fence to enclose the area. The mechanical contact between lid and fence creates the shield. In the second approach, solder paste is applied to the bare copper pads of the PCB along the traces or the perimeter where the shield is to be placed. The shield is then placed and soldered using standard reflow process. This is a one-step process. This latter approach has gained considerable popularity because it cuts out a process step and requires less PCB real estate.

SEI process. The key to a successful SEI process is to uniformly dispense a controlled amount of solder paste accurately at the edge location to provide the optimum shield interconnection. Properly implemented, the process will dispense paste on the edge copper traces such that 50% of the solder volume is on the top of the edge pad, and the remaining 50% is deposited on the side trace of the edge pad for good bonding between the shield and substrate edge. As such, the typical dispensing is in close proximity to the edge of the PCB, which creates a unique challenge. This is addressed through use of a traditional auger pump controlled by software that handles edge detection (of the PCB) for high process accuracy and controls dispensed line width.

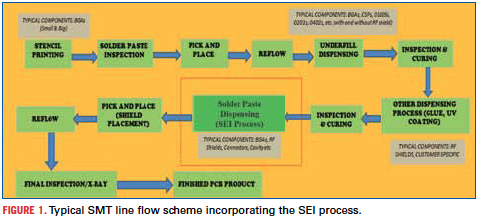

The inherent simplification of the one-step shield attachment process also creates a complete metallic (solder) bond surrounding the entire PCB that makes the RF shield highly reliable. Low-temperature Pb-free (no-clean) solder alloys are used to attach RF shields. This is because an SMT PCB assembly that includes RF shields undergoes two reflow passes: the first to attach the SMT components, and the second to attach the RF shields. Although the first pass will typically involve higher-temperature Pb-free solder (e.g., SN100C @ 227°C) to form the solder joints for the component leads, one does not want those solder joints to see liquidus or even near-liquidus temperatures a second time due to the potential for oxidation degradation, dewetting, and other problems. It is also desirable to limit the degree of thermal cycling of the board to minimize potential for damage associated with thermal stress. Consequently, second-pass reflow for shield attach is achieved using low-temperature melting alloys, such as a SnBiAg alloy with a melting temperature point below 140°C. Figure 1 shows a typical flow scheme whereby the PCB is assembled with components and reflowed in the standard manner. Following those process steps, the low-temperature solder paste for shield attach is dispensed; the shield is put in place, and the assembly is reflowed.

As mentioned, the nature of the SEI process in the SMT line is compatible with and provides advantages to other dispensing applications such as underfill, where dispensing systems can implement the underfill process without the presence of RF shield cans on the PCB. This provides a significant advantage to the underfill process, as restrictions on underfilling through the RF shield holes designed by the OEMs can be avoided.

Technology considerations for SEI. Key process control parameters essential to achieve SEI include the following:

- Precise control of solder volume dispensed per pad/interconnect area.

- PCB edge sensing accuracy – absolutely critical for this atypical dispense application.

- Ability to dispense varying solder paste types (including types 3 through 6).

- Ability to dispense pastes via varying needle sizes (IDs).

- Precise line (solder bead) width dispense accuracy.

- Repeatable consistency of deposition over high volume/throughput.

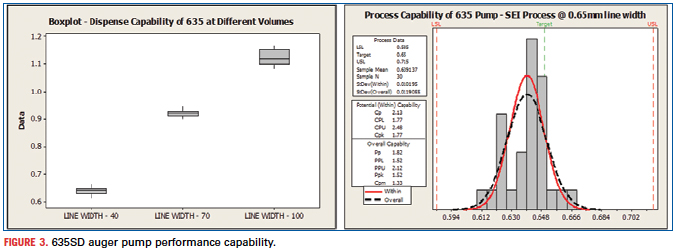

Establishing pump capability is key in developing a robust process for SEI. The Camalot Model 635 Servo Drive (SD) pump, an auger-based system, was chosen for this application. Capability analysis (Cpk) of the pump is conducted on line widths measured by dispensing different solder volumes or bead widths. Data are statistically validated with variability plots of multiple line widths (Figure 3). Results presented in Figure 3 have shown the pump capability with tolerance of 10% over average or target given by the customer. This precision is critical to the SEI process, since high variability in solder volumes can result in serious failure defects, including shorts and opens, as most of the lines are dispensed on the edge pads of the PCB where solder volume and solder bead width are critical. Such qualification was necessary in proving the suitability of this auger pump model for the SEI process.

The dispense platform chosen for SEI process development was the Camalot Prodigy, which has an accuracy of +/-35µm at 3Σ, and repeatability of +/-10µm at 3Σ. This is supported by acceleration speeds of 1.5g in motion to dispense packaging materials at independent locations.

Software capability is critical to effectively program dispense locations based on the design of the PCB and dispense requirements. “Line dispense” commands with parameters aligned to the auger pump capabilities are used to design the dispensing process. With the SEI application the challenge is to address the dispensing process for the edge pads, as the coverage area is unique to traditional solder paste dispensing. This is where a new feature that is based on vision algorithm drives to accurately locate the edge pads of the PCB and ensure accurate dispensing with optimum solder paste coverage.

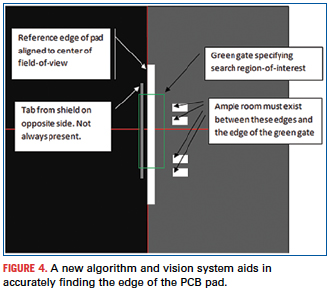

Finding the edge. A state-of-the art vision system was developed to provide the vision capabilities required by SEI. The camera system used is equipped with digital vision enhancement with sub-pixel definition. These hardware enhancements maximize the accuracy of the fiducial locations, components and pad edges, to provide additional features, including visual inspection for automatic deposition monitoring.

The primary objective is to permit the vision system to find the edges of the PCB accurately. To execute this feature, a command is used in which the user teaches the edge pads of interest. This command for edge find uses the same options as used for a standard fiducial, but instead we teach the edge of the copper pad. Figure 4 shows how a sample template appears with respect to a PCB edge pad. This figure also depicts the edge pad of the PCB with and without the RF shield on the other side, in case the SEI process requires shielding on both sides of the PCB. The software and vision capabilities show the different options for the user to teach the pad accurately. The vision system and software has the ability to distinguish the edge pad from the shield, if there is a shield present outside the edge pad, and accurately dispense on the edge of the pad.

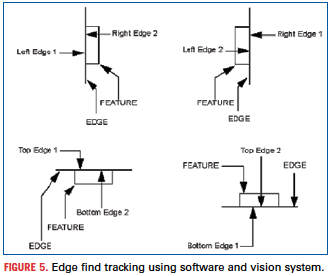

Once the edge pads are taught, the software and vision move to that position at the beginning of the SEI process and search for the second edge of the pad to trace a complete edge. Figure 5 provides a snapshot of how the software executes the search algorithm.

Figure 5 shows the edge of the PCB is traced by teaching the position of the edge pad on the PCB. If the edge pad is located on the left-hand edge of the PCB, the user selects a command to look for the second edge coming from the right to left side of the PCB. If the edge pad is located on the top edge of the PCB, the user selects a command to look for the second edge coming from the bottom to top side of the PCB. Similarly, different edge pads at different locations can be taught by the user, using the locate edge feature in the process program. It is highly recommended that the locate edge feature always be taught in pairs. The software has the capability of teaching multiple edge pads to have higher accuracy and accounts for manufacturing variability such as shape, size and discoloration.

Next, in similar fashion to the standard “dot” or “line” command, the user teaches the machine to apply the line or dot. However, in this case, the line or dot will use the reference position as the edge of the pad or PCB, such that 50% of solder volume is on top of the pad and 50% on the side of the pad. The process herein described is critical to the dispense quality along the edge pads for the SEI process.

The combination of the vision system for edge pad recognition with algorithms developed within the software enables a 9 or 13µm per pixel resolution, necessary for the vision to detect edge pads and other pads as small as 50µm in width or diameter. The combined technology takes into account the variability of the edge pad shapes, where a less-than-ideally shaped edge pad could still be detected by the vision system to ensure the right volume of solder paste is dispensed.

Line width measurement and line width adjustment features are critical to the SEI process. For this purpose, a template is designed to input some dispense parameters for dispensing lines. The pump automatically dispenses the line on the pre-dispense area, and the vision system inspects the line to compute the bead width. Line width adjustment monitors the accuracy of the amount of material dispensed and makes adjustments automatically if line widths are found out of tolerance or specification limits. This feature presents a process monitoring system critical to large-volume production.

SEI application using automated solder paste dispensing is a robust process that depends on strict process control. Implementation depends on specific capabilities in the dispenser, pump, vision system and software relative to line-width control and edge-definition capabilities. It creates a sufficiently durable RF shield connection to be suitable for mobile personal communication device assembly delivering products of high quality.

Rajiv L. Iyer is an applications engineer III at Speedline Technologies; riyer@speedlinetech.com. Michael Martel is a product marketing engineer at Speedline.