Finding Fault

Testing mission-critical functions in automotive electronics.

In the past, electronic control unit design development cycles typically took two to three years, moving in tandem with the creation and launch of each new car model. That cycle time is now down to six to 18 months. The tighter schedules have ushered in significant changes and trends in the way products are designed and tested for cost and time-to-market efficiencies.

First, there is more emphasis on communication tests instead of measurement and verification of the actual circuitries used. There is also an increasing usage of built-in tests in their designs, which are validated via communication tests.

Second, there is a shift in test strategy. Previously, conventional testing of ECUs in some applications required heavy use of inductive loads. This has given way to less reliance on inductive loads, in favor of a trend toward use of resistive loads wherever possible. Resistive load testing provides easier and more stable tests, with faster test times.

In the areas of software development, improvements are being made to algorithms and security features. Most ECUs today still use K-Line, LIN, and CAN protocols, but industry leaders believe LAN-based communication will gain popularity moving forward.

These days, automobile OEMs bear a hefty price for any defects that reach the consumer when the need for recalls is triggered. In most cases, these recalls are caused by faults that somehow still managed to escape the seemingly rigorous tests most ECUs are put through.

Arresting the escapes. Contributing factors for these escapes include, as noted, the shorter product development lifecycles mean engineers no longer have the time to verify all components and product functionalities. Second, to improve test efficiencies, focus has shifted to greater use of communication tests, with less emphasis on real measurements, contributing to potential fault escapes. This exacerbates the zero-defect tolerance of most mission-critical ECUs, from electronic-based braking systems to airbags.

Automotive electronics manufacturers are not ignoring the need to arrest these escapes. Increasingly, many test managers are looking for real-time measurement solutions to ensure not only the sum, but the parts of the whole vehicle function seamlessly and safely by the time it hits the tarmac. Manufacturers are beginning to realize that on the road, the various ECUs operate simultaneously, with thousands of concurrent real-time input and output signals triggered simultaneously. This is vastly different from pre-shipment manufacturing tests, where most measurements are done via traditional sequential input/output methodologies. Commonly witnessed escapes arising from sequential tests are cross-talks and signal spikes. In sequential tests, inputs and outputs are triggered one after another and not concurrently, as in the situation of cross-talks, where signals transmitted by one channel on a circuit can trigger an undesired interference effect in another channel on the same or even different circuits.

Typically, functional test yields in automotive ECUs are very high. The same product would have undergone rigorous test and inspection from AOI to x-ray inspection and electrical process test. As such, functional test yields are typically close to 100% after all the upstream test and inspection investments.

However, even a 100% pass does not necessarily mean the product is defect-free, as it depends on the product’s testability and test coverage. Hence, manufacturers must constantly strive to design for test and improve their test methodologies for better product quality.

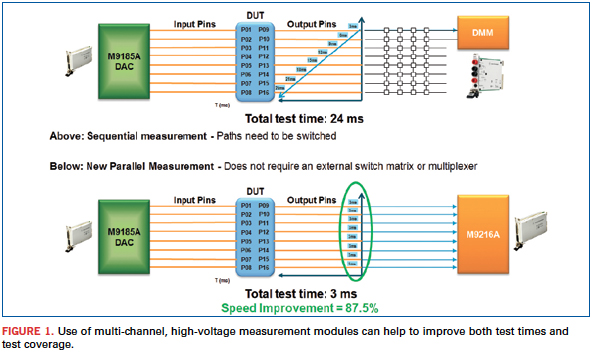

Now let’s examine the fundamental question of test: Is there a perfect solution that balances test coverage and cost viability? To meet this challenge, some manufacturers are trying to adopt parallel measurement and monitoring for ECU tests to simulate live scenarios when a vehicle is on the road. This will maximize quality assurance prior to product shipment, but the bigger challenge – lack of a cost-effective solution – remains. Digitizers are expensive, while most commonly available data acquisition modules may not meet the specifications required for testing high voltage ECUs. Multi-channel, high-voltage measurement modules are one solution to address these gaps (Figure 1).

At the R&D and design and verification stages, it is possible to run real-time monitoring for all input and output points. However, in high-volume manufacturing, it might not be practical to implement this test, as this would substantially drive up the overall test time. It is much more practical to adopt a test strategy whereby critical test points are identified after the design verification test stage, and selectively put through rigorous parallel measurements using multi-channel module. This assumes in-circuit test and even imaging inspection are deployed to take care of circuitry and device integrity of the PCB assembly upstream.

The next question is, is there such a thing as a perfect test in which all tests pass? It may seem paradoxical, but if certain test parameters show 100% passes, then there is, in fact, no need to run the test. The aim of any good test is, fundamentally, to be able to find faults. While it may not be possible to have a 100% failure-proof test, a good test strategy can achieve effective cost-of-test and provide comprehensive coverage. For functional test solution providers, the challenge is to combine best practices gathered on the ground into well-documented and practical tools, in terms of new test libraries and system capabilities. This includes gathering knowledge and experiences from R&D engineers, who understand which components and functions are critical, combined with real-time manufacturing process knowledge of potential “fault zones” that must be covered with the appropriate tests.

Some automotive electronics OEMs are already applying very comprehensive tests – combining communication tests with device verification at functional test. By deploying parallel testing at functional test, test times can be reduced substantially while boosting product quality assurance.

Looking ahead, improvement in ECU firmware can help manufacturers to take advantage of the parallel and multi-threading capabilities already present in functional test technology. If that is achievable, it would enable the DUT to fully utilize test capabilities available on leading functional testers, and improve overall product quality and safety with greater fault coverage.

Swee Chye Goh is business development manager, Agilent Technologies Automotive Functional Test Solutions; swee-chye_goh@agilent.com.