Lost Chips

If parts are turning up where they shouldn’t be, check the feeder and paste.

If parts are turning up where they shouldn’t be, check the feeder and paste.

Chip components sometimes appear on the surface of a board completely out of position. On some occasions they may be under other components or, as in FIGURE 1, even shorting under parts. If it’s a random chip component, then there is little chance of finding the cause. If all the parts are the same resistor or capacitor, it may be a feeder problem where the parts are being dropped after pickup, or are jumping out of the tape due to static, which can occur on small parts (below 0201).

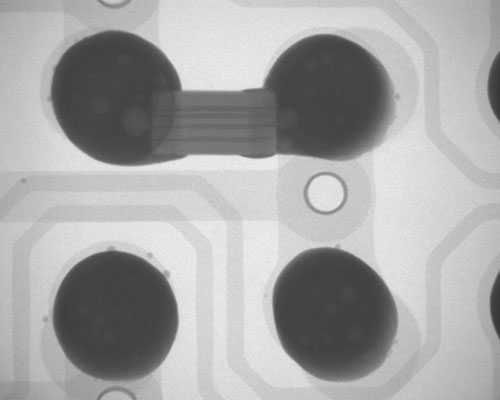

Figure 1. X-ray example of a chip cap soldered under a BGA.

Lost or misplaced components can also be seen when the placement system is working perfectly but the parts are not held by the tacky nature of the solder paste. This can occur due to the paste, poor paste volume control or high inertia of the board on older placement platforms. Vibration or high inertia should not be seen on small passives down to 0201, but the 01005 and smaller sizes can suffer from early release from the pickup nozzle. The x-ray image in Figure 1 shows a capacitor soldered between two solder balls under the BGA package.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.