Flux Spitting/Vapors and Condensation

Slow the soldering, control the problem.

Flux spitting is essentially the same problem as solder balling. It is caused by soldering at a speed too fast for the material or process settings in use. If a company were to develop new cored wire, engineers would still try to push the process window. Hence, the best way is to look at the materials and the process.

Testing and observing the soldering characteristics of the wire during heating and reflow is a very useful means to compare products. Japan Unix has used high-speed video to show the difference in wires and the degree of solder balling. Video on the company’s website shows the benefits of wire preparation prior to reflow. In our tests, we have been able to control the escape of flux volatiles from the wire and, at the same time, spitting of solder balls.

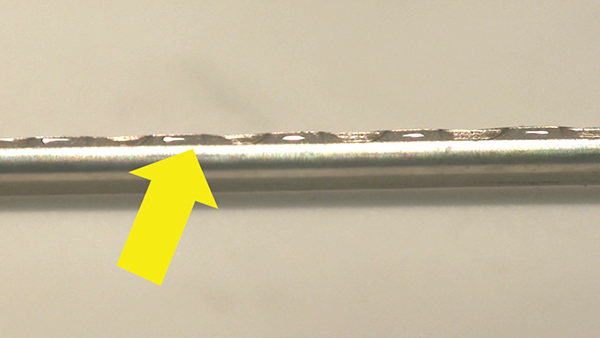

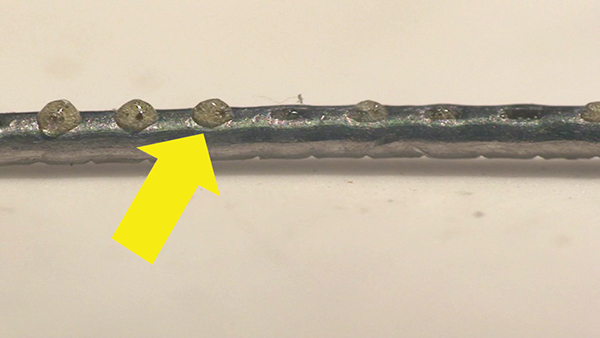

FIGURE 1 shows the point that flux escapes from the wire during heating. It also shows solder balls formed on a white ceramic tile when the wire was not prepared.

Figure 1. Arrows in the images on the left and center show the flux escapes from cored wire during heating. The image on the right shows solder balling due to unprepared wire.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the Defect Video of the Month, presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is a consultant at the National Physical Laboratory (npl.co.uk); martin.wickham@npl.co.uk. His column appears monthly.