Solder Joint Separation

When joints look perfect but nonetheless are failing, check the plating adhesion.

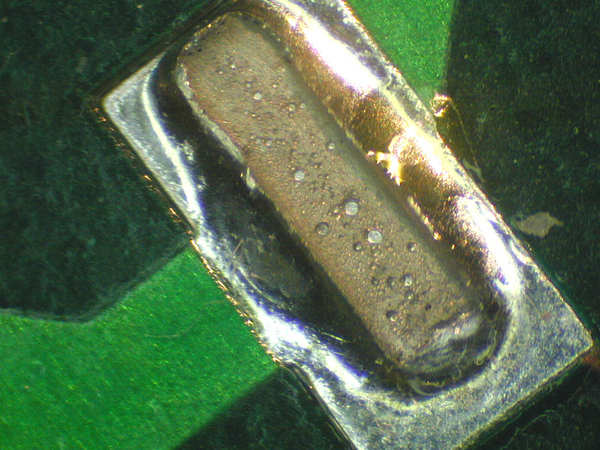

Solder joint separation or failure can happen for a variety of reasons, even when every aspect of the assembly process is working correctly. In FIGURE 1 the connector pin has separated from the surface of the printed board after reflow. The solder paste has reflowed correctly, and there is evidence on the pad of the joint and how the solder had successfully wetted up and around the contact to form a continuous fillet before the pin detached. There are some small voids in the joint, but these are very common between flush-mounted surfaces.

Figure 1. A separated connector pin post-reflow. The wetted solder suggests a plating adhesion issue.

If faced with this type of defect, take time to look at both surfaces – the PCB and connector pin – to understand and investigate the failure. In this case, there was plating separation from the connector pins. The solder paste reflow process was satisfactory, and solder wetted the plating and formed what looked like a perfect solder joint that would have passed any inspection or AOI. The plating adhesion to the base material was the problem, and just like pulling your foot out of a shoe, you are left with a perfect mold of the pin, but not a strong or reliable joint.

Conducting reflow simulations on the connector pins showed evidence of outgassing from the plating and complete dewetting on the surface of the pins. The point at which dewetting occurs may be time-dependent, and the time at reflow may not show the phenomenon. This should have been visible if solderability assessment had been conducted on the connectors. A wetting balance measurement can sometimes reveal dewetting not visible in practice.

These are typical defects shown in the National Physical Laboratory’s interactive assembly and soldering defects database. The database (http://defectsdatabase.npl.co.uk), available to all this publication’s readers, allows engineers to search and view countless defects and solutions, or to submit defects online. To complement the defect of the month, NPL features the “Defect Video of the Month,” presented online by Bob Willis. This describes over 20 different failure modes, many with video examples of the defect occurring in real time.

is with the National Physical Laboratory Industry and Innovation division (npl.co.uk); chris.hunt@npl.co.uk. His column appears monthly.