Features Articles

How lesser-known printer software features can improve process control.

As a process engineer specializing in the stencil printing operation, I understand why many operators are unaware of the bells and whistles in advanced printing platform software – especially when working in a busy production environment. While the primary focus is speed, pressure and angle to ensure the best print at the fastest cycle time cadence, sometimes the production pace can be interrupted by unexpected events. I was reminded of this – and a couple of software tricks – recently when doing evaluation work in our lab.

While 5G has only shown a fraction of its potential, will the world ever be ready for the next generation?

Much of the world seems to have changed beyond recognition since the pandemic began. With numerous economic and environmental uncertainties, however, one thing remains constant: our appetite for what comes next – and our impatience – are undiminished. The rollout of 5G cellular networks has barely begun – after a huge development effort to define the standards and do the engineering – yet, already, excitement is building around 6G. The first standardization phase for this will begin in 2023 and services should be available around 2030.

Widespread critical staffing needs call for a cross-industry effort to promote manufacturing.

With this time of year come many opportunities to attend industry gatherings, catch up with industry colleagues, and find out what’s happening in the macro circuit board supply chain. Over the past couple months, I have seen many old friends. And, I have had more than a few opportunities to reflect on our industry, the state of the supply chain, and what is “critical” versus just “important.”

Teams are overworked and on the edge. How to combat the slide.

One of my favorite bosses pointed out that a contract is only as good as the intent of the parties who sign it. Yes, you can haul a party in breach of contract into court or arbitration, but the resolution rarely completely fixes the issue, and in many cases parties breach agreements with no consequences. Nowhere is that more evident than in today’s semiconductor industry. You’ll get parts when they arrive even when there was a commitment for an earlier date; they may cost more than the agreed-upon price; and the order is noncancellable regardless of how many previously agreed-upon terms change. In short, one party has no intent to adhere to the terms of its agreements, and market conditions will likely enable that behavior to continue indefinitely with no consequences.

This type of environment can be as contagious as the most recent Covid variant. Customer service and honoring commitments are sliding across the board. Last month, I listened to a gate agent lecture a 6 a.m. flyer who foolishly thought she could get to her destination in a single day, saying the airline wasn’t obligated to put her on a different airline until she had been stuck in transit for 48 hours. Separately, three contractors I called for glass cutting informed me that they couldn’t commit to a time for quoting or delivery but would a call an hour before they arrived. One finally did call back a week later and got the job. The other two still haven’t called back. When all competitors in a market are getting away with behaving badly, mediocrity thrives.

IPC workmanship standards are getting a definition revamp.

IPC workmanship standards are used throughout the industry, in particular by OEMs and EMS companies as a way to ensure all those involved in producing printed circuit assemblies agree on what’s acceptable and what’s not.

A study of the influence of design parameters that impact success.

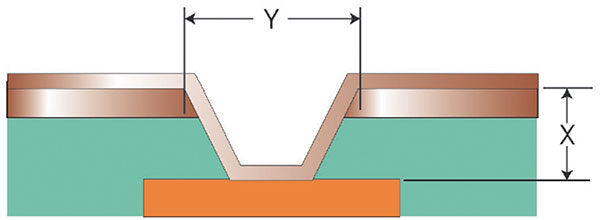

A microvia is defined in IPC-T-50M as “a blind structure (as plated) with a maximum aspect ratio of 1:1 when measured in accordance with FIGURE 1, terminating on or penetrating a target land, with a total depth (X) of no more than 0.25mm [0.00984 in] measured from the structure’s capture land foil to the target land.”

Figure 1. Microvia definition per IPC-T-50M. (Note: X/Y = microvia plating aspect ratio, with X < 0.25mm (0.00984") and aspect ratio < 1:1.)

Advantages to using microvias in PCB design include but are not limited to signal integrity, routing real estate, and pin escape. The most common reason that drives designs to use microvias is the need to escape the pins of a fine-pitch part. As pin pitch on an integrated circuit (IC) is reduced, the design starts to approach a threshold where mechanically drilled vias are not possible. When this happens, other routing solutions such as microvias are required. Use of area array components with a pitch of less than 0.8mm will very likely require the use of microvias to escape the pins of the component, and these components are becoming common in high-reliability electronics such as space hardware and military/defense products. Another advantage is microvias can be used to make connections between two adjacent layers, thus saving a significant amount of routing real estate by not requiring a via that spans multiple layers as a mechanically drilled via typically would. And microvias help with signal integrity of high-speed digital or radio frequency (RF) circuits. At higher frequencies designs can be very sensitive to signal reflection caused by via stubs, and microvias may be required to mitigate signal integrity issues.