Managing Your Environmental Waste

An outline of procedures for determining and recycling hazardous material.

Electronics manufacturers create many types of waste within a facility. Here, we look at the different types of waste, identification of hazardous waste, and wastes which can be recycled to help the environment.

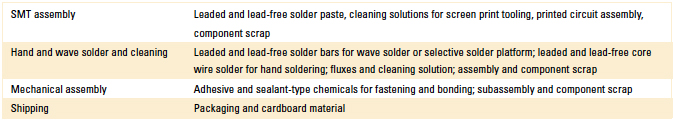

Manufacturing materials are used within an electronics manufacturing facility in the SMT area, hand and wave solder, mechanical assembly and in the shipping department. These materials assist in the manufacturing of electronic product. TABLE 1 details a sample of potential manufacturing materials per area.

Table 1. Examples of Wastes by Area

Understanding environmental regulations can be cumbersome. The key is to stay informed through workshops, websites and environmental compliance updates.

EPA and state environmental departments offer workshops relating to regulations, compliance and reporting requirements. The overall goal is to understand if specific waste is hazardous or nonhazardous and how to properly dispose of it.

The determination if a waste is hazardous can be completed by following the rules within the Resource Conservation and Recovery Act (RCRA) regulation. A testing approach such as a Toxicity Characteristic Leaching Procedure (TCLP) can determine which substances are hazardous within a given testing sample and determine if they are below or above the threshold. This testing approach is typically a sure way to determine if a waste is hazardous.

Contained within the new Safety Data Sheets (SDS) are pictograms (FIGURE 1) which will provide basic hazards of the waste and classification if the waste is flammable. This SDS will also provide the ingredients and a starting point for the hazardous waste determination.

Figure 1. Global Harmonized System (GHS) pictograms.

After waste has been determined to be hazardous, proper disposal is required per federal and state guidelines. FIGURE 2 shows an example of hazardous waste storage within an electronics facility. In this specific example, the yellow container is for leaded waste, including components. The red container is used for flammable waste, which may include adhesive and bonding chemicals.

Figure 2. Hazardous waste containers.

When assessing wastes, investigate the byproducts of a specific process and the total waste stream. If a material is determined to be a hazardous waste through TCLP testing, then any tool, equipment or production aid that comes into contact may also be classified as a hazardous waste. It is important to search throughout the entire facility, especially cleaning processes and secondary processes such as a conformal coat operation.

Cleaning processes may include filtration systems to clean and collect contaminants. Waste from the filtration system may contain metals and chemicals from the SMT process. The conformal coat process involves applying a coating to printed circuit assemblies to protect from harsh environments, typically for the industrial, military and aerospace industries. Waste from the coating process may also include touchup and rework of an assembly.

Recycling and reuse opportunities. Many items within an electronics manufacturing facility can be recycled and reused. Assess your situation and research your federal, state and local environmental regulations to determine whether the specific waste can be recycled. The decision as to whether the waste can be recycled may take a waste determination or a TCLP test, as noted above. The item may also be a candidate for reuse within a facility. Typically packaging, fixtures and potentially other waste can be reused within an operation. Another opportunity may be to set up a recycling packaging program with a supplier or customer. This can be justified by many factors, such as distance, time to support and cost.

Scrap and unusable electronic assemblies, subassemblies and individual components might be candidates for recycling. The determination requires an assessment and research before making such determination. Solder dross (lead and lead-free) is another example of material that may be recycled, given its characteristics and metal content. The metal content in solder dross is high, and given market pricing, the cost payback can be substantial, as discussed in the section below.

Other opportunities exist within a facility with computer equipment, scrap metal such as piping, tooling and fixtures. Fiber recycling can include printer paper, company magazines, and packaging material, all of which may be recycled, especially cardboard if not a candidate for reuse.

Potential cost and environmental payback. The major payback of most electronics manufacturing waste recycling activities is the metal content (tin, copper, silver, lead, etc.), which is refined and extracted by the recycling supplier. These metals are found in the wave solder dross, components, hardware and other scrap metals found within the operation. As an example, in 2015 recycling lead-free wave solder dross provided a cost payback of approximately $10 per lb. of lead-free dross (SAC 305). This equates to a cost payback of roughly $1,000 per 100 lb. of recycled lead-free dross material.

Through understanding an electronics manufacturing facility’s waste stream, the operation can identify and manage its waste properly. Some waste will need to be disposed of by following federal and state disposal rules, while other waste might be recyclable. This recycling activity may provide the operation with a cost payback, along with ultimately helping the environment by managing waste properly.

References

1. Scott Mazur, “Benefits of an EMS for the EMS,” CIRCUITS ASSEMBLY, August 2011.

2. Scott Mazur, “Environmental Recycling for the EMS,” SMT, October 2010.

is manufacturing staff engineer and environmental management representative, Benchmark Electronics (bench.com), and a contributing author to Green Electronics – Design and Manufacturing; scott.mazur@bench.com.

Press Releases

- Phononic Launches Wholly Owned Subsidiary in Thailand as APAC Headquarters

- AIM Solder’s Dillon Zhu to Present on Ultraminiature Soldering at SMTA China East

- Hentec/RPS Publishes an Essential Guide to Selective Soldering Processing Tech Paper

- ZESTRON Welcomes Whitlock Associates as New Addition to their Existing Rep Team in Florida